Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Chemical Family

- Country of Origin

- Function

- Crosslinking Agent

- Plastics & Elastomers Functions

- Product Code

- MITM02831

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

Applications & Uses

- Plastics & Elastomers End Uses

Properties

- Physical Form

- Product Reactivity

Reactivity Profile at 70°C Time (seconds) Cream 72 Gel 211 Free Rise 269 Tack Free 331

Technical Details & Test Data

- Technical Data

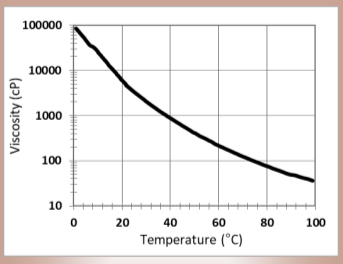

Viscosity Information -

- 77 °F - 3700 cP

- 120 °F - 450 cP

- 140 °F - 200 cP

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S001809

- Principal

Storage & Handling

- Storage Conditions

CARPOL® GSP-355 will absorb water if the product container is not secured properly. This may affect reactivity, appearance, and performance. Therefore, it is advised that all receptacles containing this material be tightly fastened and stored in a dry place.

Other

- Appearance

- Free and clear

- Item Number

- Odor (SDS)

- Slight sweet odor

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions Hydroxyl Value 355.0 mg KOH/g mg KOH/g pH 7.0 - 1% 10:6 IPA:Water - Material Composition

Value Units Test Method / Conditions Potassium Content max. 10.0 ppm ppm - Mechanical Properties

Value Units Test Method / Conditions Compressive Strength 345.0 psi psi parallel Compressive Strength 325.0 psi psi PET, at 1/3 standard depth with 1% titanium dioxide (ABS 4% titanium dioxide, PS 2% titanium dioxide) Flexural Strength 520.0 psi psi - Optical Properties

Value Units Test Method / Conditions Color Scale max. 7.0 Gardner Gardner Gardner Color Scale - Physical Properties

Value Units Test Method / Conditions Density 9.11 lb/gal lb/gal at 25°C Density 6.9 lb/in³ lb/in³ Moisture Content max. 0.08 % % Viscosity 3700.0 cPs cPs at 25°C - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Flash Point (SDS) min. 200.0 °F °F Specific Gravity (SDS) 1.1 - Water = 1 pH (SDS) 7.0 - - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 0.0 d d