Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Function

- Leveling Agent

- Product Code

- MITM11392

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

Applications & Uses

- Application Area

- Coating End Applications

- Compatible Substrates & Surfaces

- Markets

- Applications

- Product Applications

- The results of laboratory tests comparing the performance properties of RHOPLEX® SG-10AF against RHOPLEX® AC-417M Emulsion, a basic time-proven acrylic vehicle, are included in this bulletin to demonstrate the unique performance characteristics of RHOPLEX® SG-10AF in interior paints.

- Years of exposure and commercial experience demonstrate the excellent exterior durability to expect from RHOPLEX® SG-10AF

Application and Performance Properties:

- Flow-

- The excellent flow properties of a formulation based on RHOPLEX® SG-10AF are much better than those of a formulation based on RHOPLEX® AC-417M Emulsion.

- RHOPLEX® SG-10AF is designed for maximum performance with associative rheology modifiers and is superior to commercial acrylic and vinyl/acrylic polymers.

- Block Resistance-

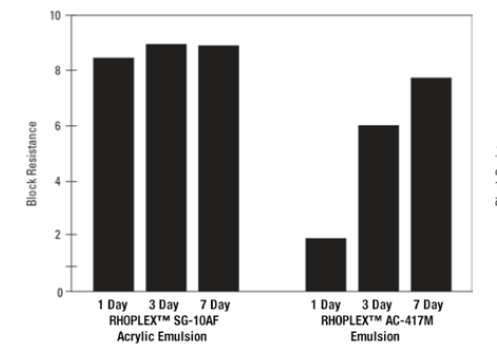

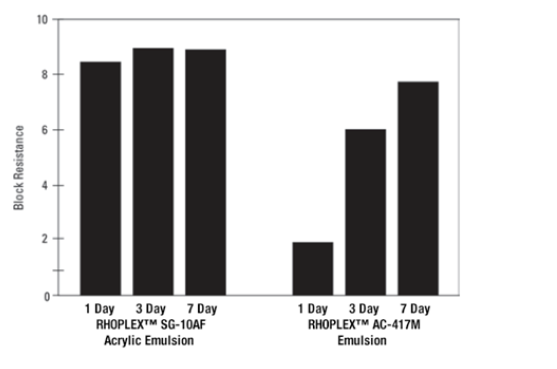

- Figures 1 and 2 illustrate the dramatically superior block resistance obtained by using RHOPLEX® SG-10AF instead of HOPLEX® AC-417M.

- Emulsion tests conducted over a seven day period at room temperature and at 120°F. There is rapid development of block resistance with no film damage after one day at room temperature.

- Figure 2 also shows the excellent performance of coatings based on RHOPLEX® SG-10AF at elevated temperatures.

Figure 1: Room Temperature Block Resistance RHOPLEX® SG-10AF vs. RHOPLEX® AC-417M Emulsion

Figure 2: High Temperature Block Resistance RHOPLEX® SG-10AF vs. RHOPLEX® AC-417M Emulsion

-

Scrub Resistance-

-

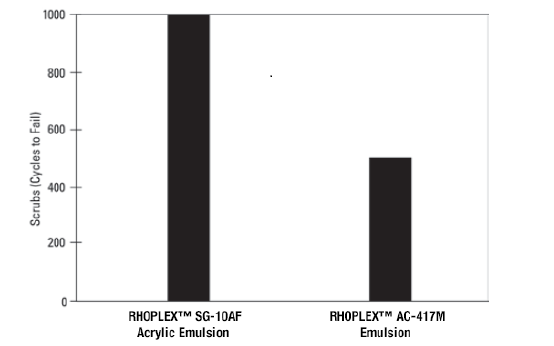

The superior abrasive scrub resistance furnished by formulations based on RHOPLEX® SG-10AF over those based on RHOPLEX® AC-417M Emulsion is shown in Figure 3.

-

Moreover, the use of RHOPLEX® SG-10AF produces an excellent balance of adhesion and scrub resistance.

-

Figure 3: Abrasive Scrub Resistance RHOPLEX® SG-10AF vs. RHOPLEX® AC-417M

Properties

- Physical Form

Safety & Health

- Safety Precautions

Based on the character of similar materials, RHOPLEX® SG-10AF is not expected to be toxic via single acute oral or dermal exposure. It may be a mild-to-moderate skin and eye irritant.

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000005

- Principal

Storage & Handling

- Handling Information

- As with all hard emulsion polymers, special care should be taken with RHOPLEX® SG-10AF SG-10AF Acrylic Emulsion to avoid the formation of dried polymer particles that can cause grit problems.Recommended that the material be filtered before the emulsion is pumped into the letdown vessel. Filter bags with 100-250 micron (150-60 mesh) size have proven effective. Another situation to avoid while handling the emulsion is the generation of foam. There should be no free fall of emulsion. It is imperative that suitable materials of construction of tanks, pumps, lines, and other auxiliary equipment be used. We recommend stainless steel or plastic.

- CAUTION! Keep combustible and/or flammable products and their vapors away from heat,sparks, flames and other sources of ignition including static discharge. Processing or operating at temperatures near or above product flashpoint may pose a fire hazard. Use appropriate grounding and bonding techniques to manage static discharge hazards.

- CAUTION! Failure to maintain proper volume level when using immersion heaters can expose tank and solution to excessive heat resulting in a possible combustion hazard, particularly when plastic tanks are used.

-

Store products in tightly closed original containers at temperatures recommended on the product label.

Other

- Appearance

- Milky white liquid

- Color (SDS)

- Off-white

- Item Number

- Protect from Freezing

- Yes

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions pH 8.5-9.0 - - Material Composition

Value Units Test Method / Conditions Solid Content 50.0 % % - Physical Properties

Value Units Test Method / Conditions Bulking Value 0.113 gal/lb gal/lb as wet Bulking Value 0.106 gal/lb gal/lb dry solids Density 8.82 lb/gal lb/gal At 25°C Film Forming Temperature 16.0 °C °C Specific Gravity 1.1 - at 25°C Storage Temperature 34.0-120.0 °F °F Viscosity 50.0-400.0 cPs cPs Brookfield Viscometer At 25°C, #2, 60 Грm - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) 100.0 °C °C at 760 mmHg Relative Vapor Density (SDS) max. 1.0 - Air = 1 Vapor Pressure (SDS) 17.0 mm Hg mm Hg at 20°C pH (SDS) 8.5-9.1 - - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 0.0 d d