Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Country of Origin

- Function

- Adhesion Promoter, Coupling Agent

- Product Code

- MITM11718

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

- Benefits

- Excellent improvement of adhesion to aluminum and steel

- Improves hardness

- Improves corrosion resistance

Applications & Uses

- Coating End Applications

- Compatible Substrates & Surfaces

- Ink & Toner End Applications

- Markets

- Applications

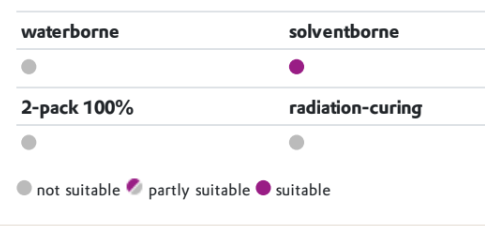

- Product Suitability

- Applications

- General industrial coatings

- Can coatings

- Coil coatings

- Transportation coatings

- Processing Information

Addition as supplied during thelet-down is recommended

- Dosage Information

Solid calculated on main binder solid: 3.0 - 15.0%

Properties

- Physical Form

- Soluble In

Packaging & Availability

Principal Information

- Group Principal Number

- S000006

- Principal

Storage & Handling

- Storage and Handling Conditions

When stored in an original unopened packaging between -10 and +30 °C, the product has a shelf life of at least 36 months from the date of manufacture.

Other

- Appearance

- Clear liquid

- Color (SDS)

- Colorless

- IATA/ICAO Proper Shipping Name

- Resin solution

- IATA/ICAO UN Number

- UN 1866

- IMO/IMDG EmS Fire

- F-E

- IMO/IMDG EmS Spill

- S-E

- IMO/IMDG Proper Shipping Name

- Resin solution

- IMO/IMDG UN Number

- UN 1866

- Item Number

- Odor (SDS)

- Aromatic

- Other Hazards

- Static accumulating flammable liquid can become electrostatically charged even in bonded and grounded equipment.

- Temperature Control

- No

- USA/DOT Emergency Response Guide Number

- 127

- USA/DOT Proper Shipping Name

- Resin solution

- USA/DOT UN Number

- UN 1866

- Application Information

Value Units Test Method / Conditions Dosage (Use Level) 3.0-15.0 % % - Chemical Properties

Value Units Test Method / Conditions Hydroxyl Value 30.0 mg KOH/g mg KOH/g calculated on non-volatile content - Material Composition

Value Units Test Method / Conditions Active Content 60.0 % % - Physical Properties

Value Units Test Method / Conditions Viscosity 500.0 - at 23°C - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) 139.6 °C °C Density (SDS) 1.05 g/cm³ g/cm³ DIN 51757 at 20°C Flash Point (SDS) 27.0 °C °C DIN 53213 Solubility In Water (SDS) max. 0.2 g/L g/L at 20°C Vapor Pressure (SDS) 7.0 - at 20°C Viscosity (SDS) 350.0-650.0 - DIN 53214 at 23°C - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 36.0 -