Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Chemical Family

- Country of Origin

- Function

- Thickener

- Product Code

- MITM11244

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

- Product Features and Benefits

Features

- A 30% solids emulsion; ease of incorporation

- Cost-effective versus low and medium molecular weight HECs.

- Higher low shear viscosity

- Does not itself support microbial growth

Benefits

- Reduced labor costs as no predilution or preneutralization required.

- Lower RM costs.

- Prevents pigment settling

- Reduced RM and overhead costs resulting from lower biocide levels and fewer product returns.

Applications & Uses

- Markets

- Applications

- Product Applications

- ACRYSOL™ TT-615 is an alkali swellable thickener, which achieves its thickening effect when it is neutralized. When added full strength to the letdown, care must be taken to avoid local shock or gross paint instability. There must be sufficient base in the system before the addition of ACRYSOL™ TT-615 to fully neutralize the thickener and still remain on the alkaline side over the normal shelf life of the paint.

- ACRYSOL™ TT-615 should be added slowly with good agitation. If this approach is not sufficient, ACRYSOL™ TT-615 can be diluted 1:1 or 2:1 with water prior to addition to the letdown to reduce the chance for shocking.

Properties

- Physical Form

Technical Details & Test Data

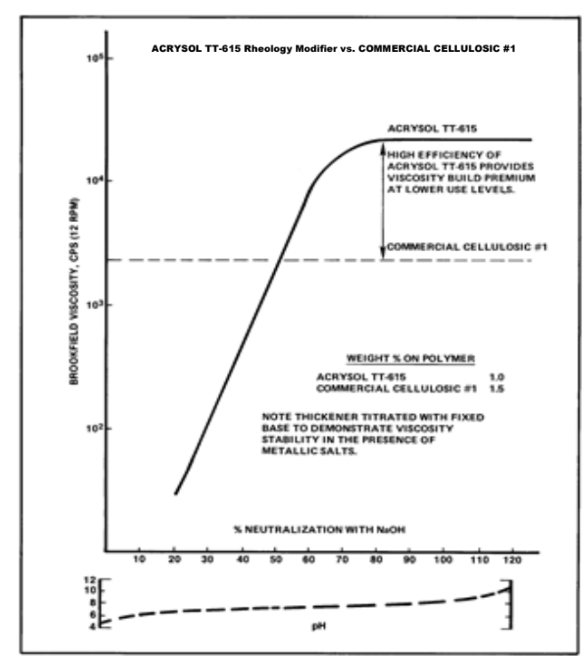

- Graph of Viscosity Vs Percent Neutralization and pH

Viscosity Vs Percent Neutralization and pH

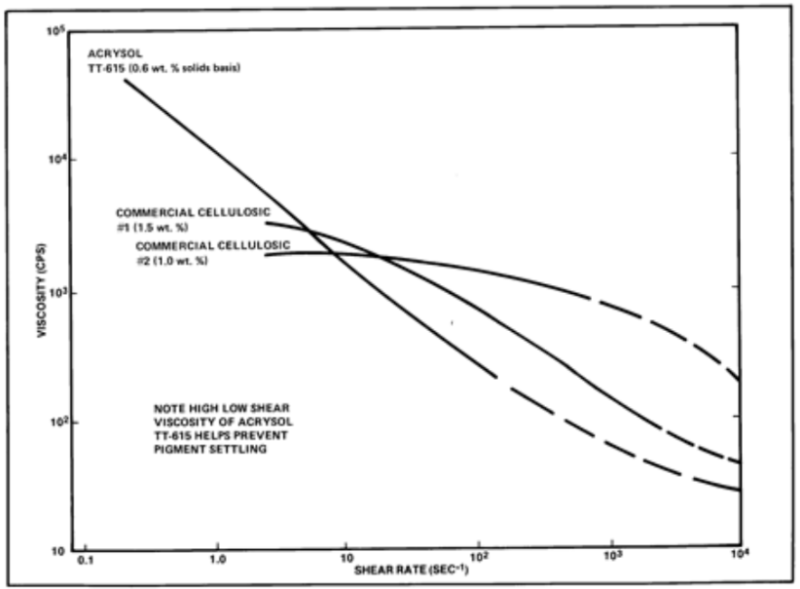

- Viscosity/shear Rate Profile of Thickeners in Water Graph

Viscosity/shear Rate Profile of Thickeners in Water

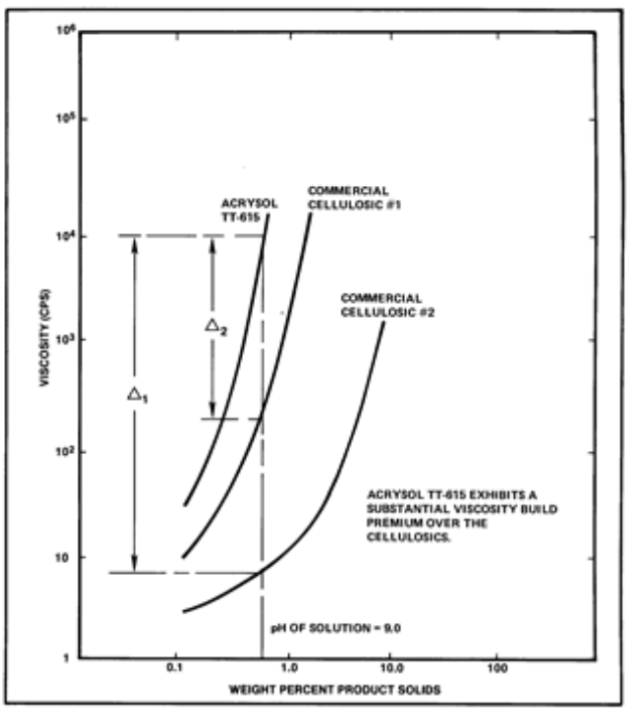

- Viscosity vs Weight Percentage Graph

Thickener Viscosity Development In Water

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000005

- Principal

Storage & Handling

- Handling Information

- Dispose of ACRYSOL™ TT-615 in accordance with all local, state and federal regulations. Empty containers may contain hazardous residues.

- ACRYSOL™ TT-615 and its container must be disposed in a safe and legal manner.

- Storage Conditions

ACRYSOL™ TT-615 is stored in tightly closed original containers at temperatures recommended on the product label.

Other

- ADR/RID/ADN Proper Shipping Name

- Not Applicable

- ADR/RID/ADN UN Number

- Not Applicable

- Appearance

- Off white milky liquid

- Color (SDS)

- White milky

- IATA/ICAO Proper Shipping Name

- Not Applicable

- IATA/ICAO UN Number

- Not Applicable

- IMO/IMDG Proper Shipping Name

- Not Applicable

- IMO/IMDG UN Number

- Not Applicable

- Item Number

- Odor (SDS)

- Acrylic odor

- Other Hazards

- This product contains no substances assessed to be PBT or vPvB at levels of 0.1% or higher.

- Protect from Freezing

- Yes

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions Equivalent Weight 218.0 g/eq g/eq weight of polymer solids exactly neutralized by 40g of solid sodium hydroxide pH 3.0 - - Material Composition

Value Units Test Method / Conditions Active Polymer Content 30.0 % % Solid Content 30.0 % % - Physical Properties

Value Units Test Method / Conditions Density 8.75 lb/gal lb/gal At 25°C Storage Temperature 33.8-120.2 °F °F Viscosity 20.0 cPs cPs Brookfield Viscometer 1/60, as packed - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) 100.0 °C °C Water Boiling Point (SDS) 100.0 °C °C at 760 mmHg, water Evaporation Rate (SDS) max. 1.0 % % Butyl acetate = 1 Evaporation Rate (SDS) max. 1.0 % % Butyl acetate = 1, water Melting Point (SDS) 0.0 °C °C Water Relative Vapor Density (SDS) max. 1.0 - Air = 1, Water Relative Vapor Density (SDS) max. 1.0 - Air = 1 Specific Gravity (SDS) 1.0-1.2 - Water = 1 Vapor Pressure (SDS) 2266.48 - At 20°C, Water Vapor Pressure (SDS) 2266.48 - at 20°C Viscosity (SDS) 1.0-35.0 - Volatile Content (SDS) 69.0-71.0 % % Water pH (SDS) 2.2-3.2 - - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 540.0 -