Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Carrier

- Chemical Family

- Function

- Crosslinking Agent

- Product Code

- MITM00230

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Coating End Applications

- Compatible Polymers & Resins

- Markets

- Applications

- Formulation Stability

- The stability of solvent-borne systems containing CYMEL® 202 Resin can be enhanced by the addition of primary alcohols, amines, or a combination of these. Low molecular weight primary alcohols such as ethanol and n-butanol are most effective.

- Recommended amines are TEA, DMEA or 2-AMP at a concentration of 0.5-1.0% on total binder solids. For best stability in waterborne systems, a pH of 7.5-8.5 should be maintained using tertiary amines only.

Properties

- Physical Form

- Soluble In

Technical Details & Test Data

- Backbone Polymer Selection

CYMEL® 202 Resin is an effective crosslinker for backbone polymer resins containing hydroxyl, carboxyl, and amide functional groups, such as those found on alkyd, polyester or acrylic resins. Although the optimum level of CYMEL® 202 Resin should be determined experimentally, ratios of 25 to 35% based on resin solids are typically most effective.

- Catalysis Information

CYMEL® 202 Resin may not require the addition of an acid catalyst to the formulation to obtain effective cure. In many instances, the acidity of the backbone polymer in the formulation is sufficient to catalyze the reaction under normal baking conditions (15-20 minutes at 120-150°C). If catalyst addition is required, then 0.5-1.0% of CYCAT® 296-9 catalyst based on total resin solids is recommended.

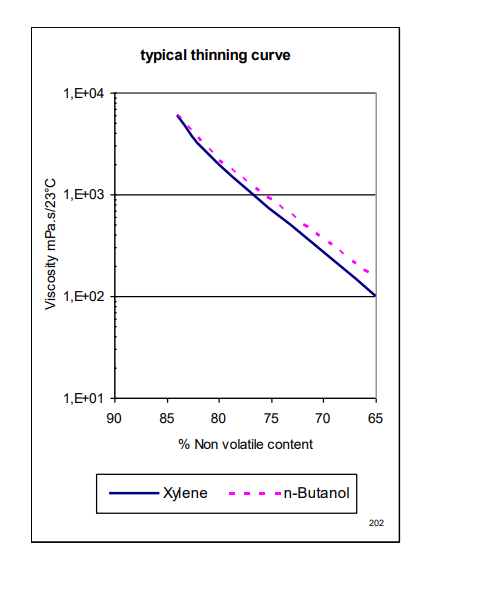

- Typical Thinning Curve

Packaging & Availability

Principal Information

- Group Principal Number

- S000001

- Principal

Storage & Handling

- Storage Conditions

- CYMEL® 202 Resin has a shelf life of 2 years from the date of manufacture when stored at temperatures between 5°C and 30°C. Although lower temperatures are not detrimental to stability, its viscosity will increase, possibly making the resin difficult to pump or pour.

- The viscosity will reduce again on warming, but care should be taken to avoid excessive local heat as this can cause an irreversible increase in viscosity.

Other

- Appearance

- Clear liquid

- Appearance (SDS)

- Liquid

- Color (SDS)

- Clear

- IATA/ICAO Proper Shipping Name

- Resin solution

- IATA/ICAO UN Number

- UN1866

- IMO/IMDG Proper Shipping Name

- Resin solution

- IMO/IMDG UN Number

- UN1866

- Item Number

- Odor (SDS)

- Formaldehyde and butanol

- Other Hazards

- Not applicable

- Protect from Freezing

- No

- TDG Canada Proper Shipping Name

- Resin solution

- TDG Canada UN Number

- UN1866

- Temperature Control

- Yes

- USA/DOT Proper Shipping Name

- Resin solution

- USA/DOT UN Number

- UN1866

- Application Information

Value Units Test Method / Conditions Application pH 7.5-8.5 - Dosage (Use Level) 0.5-1.0 % % - Chemical Properties

Value Units Test Method / Conditions Free Formaldehyde Content max. 0.6 % % Sulfite Method - Material Composition

Value Units Test Method / Conditions Non-Volatile Content 78.0-82.0 %(W/W) %(W/W) at 105°C, 3 h, Pan Non-Volatile Content 80.0-84.0 %(W/W) %(W/W) at 45°C, foil, 45 min - Optical Properties

Value Units Test Method / Conditions Color Scale max. 70.0 APHA APHA Color Scale max. 70.0 Gardner Gardner ISO 6271 - Physical Properties

Value Units Test Method / Conditions Storage Temperature -4.0-89.6 °F °F Viscosity 2500.0-7500.0 mPa.s mPa.s - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Density (SDS) 1.07-1.1 g/cm³ g/cm³ Flash Point (SDS) 47.0 °C °C SetaFlash Closed Cup Volatile Content (SDS) 16.0-22.0 %(W/W) %(W/W) - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 2.0 yr yr