Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Carrier

- Chemical Family

- Country of Origin

- Function

- Crosslinking Agent

- Product Code

- MITM13488

- Single Ingredient

- Yes

- Technologies

- Product Families

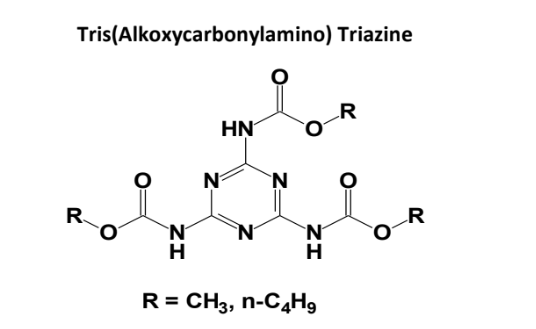

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

- Product Benefits

- Excellent environmental etch resistance

- Excellent exterior durability

- Non-formaldehyde chemistry

- Non-isocyanate chemistry

- Cure compatibility with other crosslinkers

- Low equivalent weight / high efficiency

- Low human toxicity

Applications & Uses

- Coating End Applications

- Compatible Polymers & Resins

- Markets

- Applications

- Dosage Information

- CYMEL® NF 2000A Resin can be used in water-reducible resins and with waterborne dispersions.

- Although it is water insoluble, it can be incorporated into a water-reducible system by blending with the backbone resin prior to amine neutralization.

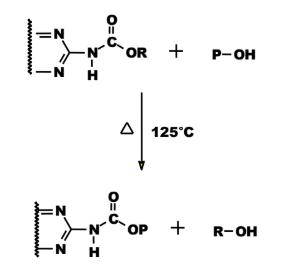

- These systems can be cured at ~125°C to give clear, high gloss films with excellent resistance properties.

- When using the material in water-based systems it is recommended that a tertiary amine be utilized as the neutralizing agent for the system in order to avoid the possibility of degrading the CYMEL® NF 2000A Resin.

- Dosage Information

- A significant advantage of CYMEL® NF 2000A Resin is its cure compatibility with other thermoset chemistries.

- Since its cure response with hydroxy-functional resins is not appreciably inhibited by amines, acids, or metal catalysts, it can be used effectively as a co-crosslinking agent with other materials, such as traditional aminoplasts or isocyanates.

- Incorporation of low levels of CYMEL® NF 2000A Resin (e.g. 1-5 wt. % on total resin solids) into a conventional polyol/aminoplast coating formulation can significantly improve the exterior durability of the cured film.

- Product Applications

- Automotive topcoats

- Coil coatings

- Exterior can coatings

- Solvent-borne and waterborne coatings

Properties

- Physical Form

- Soluble In

- Product Reactivity

CYMEL® NF 2000A Resin contains a combination of butyl and methyl carbamate functionality which enables it to crosslink backbone polymers containing hydroxy, epoxy and carboxy functionality.

- Unlike conventional amino resins, CYMEL® NF 2000A Resin has very little tendency to self-react during cure, so its effective equivalent weight is in the range of 120-130.

- In formulations where it is employed as the sole crosslinker, the level of CYMEL® NF 2000A Resin is normally adjusted to provide a ratio of 1.0 - 1.1 equivalents of carbamate functionality per equivalent of backbone polymer functionality.

- CYMEL® NF 2000A Resin reacts with hydroxy functional backbone resins at >125°C bake schedules to form urethane linkages.

- Cure can typically be accomplished without use of a catalyst to yield films that exhibit excellent hardness, chemical resistance, exterior durability and environmental etch resistance. Addition of low levels of acid catalyst (e.g. 0.5% dodecyl benzene sulfonic acid on binder solids) has been found to improve humidity resistance properties in some systems.

- Both catalyzed and uncatalyzed formulations show good 1K package stability at 23°C.

- CYMEL® NF 2000A Resin will react with carboxy functional backbone resins, but requires bake temperatures >150°C.

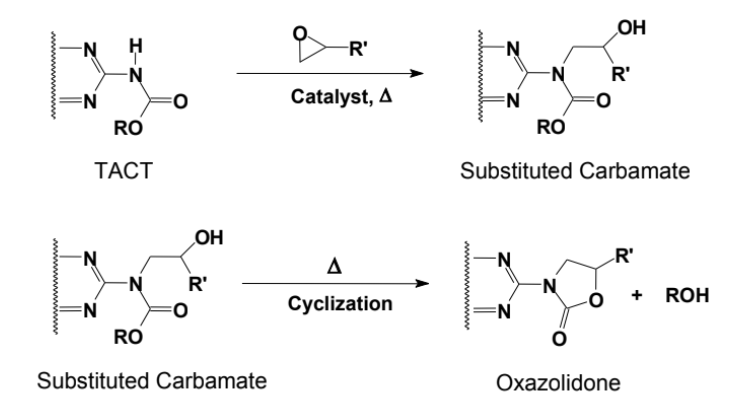

- CYMEL® NF 2000A Resin reacts very efficiently with epoxy functional resins at ~125°C resulting in N-substituted carbamate and oxazolidone crosslinks.

- Films produced through this cure mechanism often show a favorable combination of environmental etch resistance and mar resistance properties.

- In most cases, a tertiary amine or quaternary ammonium catalyst such as 4-dimethyl- aminopyridine should be employed in the formulation.

- However, catalyzed pot life can be limited, making it necessary to treat these as two-component systems.

- Notes

¹ Product may become hazy during storage as the active ingredient is near its solubility limit in solution. The haze development has no impact on performance of the product or the clarity of resulting films.

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000001

- Principal

Storage & Handling

- Storage Conditions

- CYMEL® NF 2000A Resin has a shelf life of 720 days from the date of manufacture when stored at temperatures below 32°C.

Other

- Appearance (SDS)

- Low viscosity liquid

- Color (SDS)

- Colorless to pale yellow

- IATA/ICAO Proper Shipping Name

- Flammable liquid, N.O.S.

- IATA/ICAO Technical name (N.O.S.)

- Butanol, tris carbamoyl triazine

- IATA/ICAO UN Number

- UN1993

- IMO/IMDG Proper Shipping Name

- Flammable liquid, N.O.S.

- IMO/IMDG Technical name (N.O.S.)

- Butanol, tris carbamoyl triazine

- IMO/IMDG UN Number

- UN1993

- Insoluble in (SDS)

- Water

- Item Number

- Odor (SDS)

- Butanol

- Other Hazards

- Not applicable

- Protect from Freezing

- Yes

- TDG Canada Proper Shipping Name

- Flammable liquid, N.O.S.

- TDG Canada Technical name (N.O.S.)

- Butanol, tris carbamoyl triazine

- TDG Canada UN Number

- UN1993

- Temperature Control

- Yes

- USA/DOT Proper Shipping Name

- Flammable liquid, N.O.S.

- USA/DOT Technical name (N.O.S.)

- Butanol, tris carbamoyl triazine

- USA/DOT UN Number

- UN1993

- Chemical Properties

Value Units Test Method / Conditions pH 3.0-6.0 - DIN 55659-1 - Material Composition

Value Units Test Method / Conditions Non-Volatile Content 48.0-52.0 % % DIN EN ISO 3251 at 105°C, 2 hrs, Pan Sodium Content max. 100.0 ppm ppm Inductively Coupled Plasma Mass Spectrometry - Optical Properties

Value Units Test Method / Conditions Color Scale max. 50.0 APHA APHA Color Scale max. 50.0 Gardner Gardner DIN EN ISO 6271 Turbidity max. 2.5 NTU NTU DIN EN 27027 - Physical Properties

Value Units Test Method / Conditions Storage Temperature 41.0-86.0 °F °F Viscosity 10.0-50.0 mPa.s mPa.s DIN EN ISO 3219 at 23°C - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Autoignition Temperature (SDS) 355.0 °C °C Boiling Point (SDS) 130.0 °C °C At 101.3 Kpa Density (SDS) 0.99 g/cm³ g/cm³ Flammability Limits (SDS) 1.2-10.2 %(V/V) %(V/V) Flash Point (SDS) 42.0 °C °C DIN 53213 Vapor Pressure (SDS) 4.0 mbar mbar at 20°C Viscosity (SDS) 10.0-50.0 mPa.s mPa.s at 23°C pH (SDS) 4.5-6.0 - 50% aqueous solution - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 720.0 d d