Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Chemical Name

- Function

- Reactive Diluent

- Product Code

- MITM00344

- Single Ingredient

- Yes

- Technologies

- Product Families

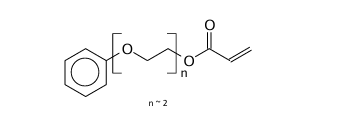

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Performance Highlights

EBECRYL® 110 is characterized by:

- Low viscosity

- Reduced odor relative to 2-Phenoxyethyl acrylate

- Excellent diluency

- High refractive index

UV/EB curable formulated products containing EBECRYL® 110 are characterized by:

- Good flexibility

- Higher refractive index

The actual properties of UV/EB cured products also depend on the selection of the other formulation components such as oligomers, additives and photoinitiators.

Applications & Uses

- Coating End Applications

- Compatible Polymers & Resins

- Cure Method

- Ink & Toner End Applications

- Markets

- Applications

- Product Applications

EBECRYL® 110 is recommended as a reactive diluent for:

- Coatings and screen inks on flexible and semi-rigid plastics including polyolefins

- Optical fiber coatings

- High refractive index coatings

Properties

- Physical Form

Technical Details & Test Data

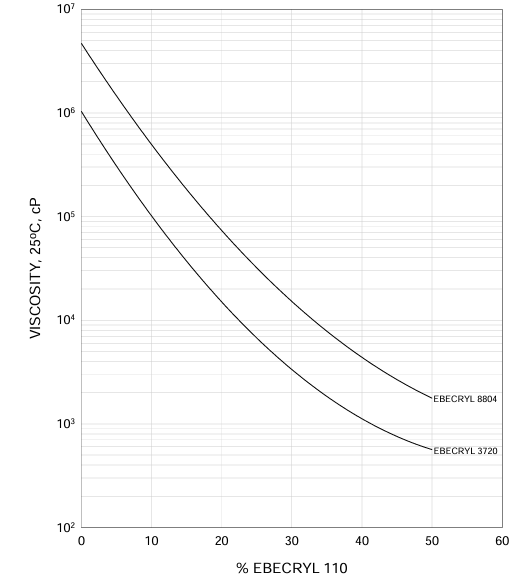

- Diluency Effect on Viscous Oligomers

Graph shows the viscosity reduction of two EBECRYL oligomers when blended with an increasing weight percent of EBECRYL® 110. EBECRYL 3720(1) is a bisphenol A based epoxy diacrylate. EBECRYL 8804(1) is an aliphatic urethane diacrylate.

Safety & Health

- Safety Precautions

- Avoid contact with eyes, skin and clothing.

- Direct contact with this material may cause mild eye and skin irritation.

- Repeated or prolonged dermal contact may cause allergic skin reactions.

- Wash thoroughly after handling.

- Use with adequate ventilation.

- Keep container closed.

Packaging & Availability

Principal Information

- Group Principal Number

- S000001

- Principal

Storage & Handling

- Storage Conditions

- Before using EBECRYL® 110, consult the Safety Data Sheet for additional information on safety and handling procedures, and recommended personal protective equipment.

- The recommended storage temperature for EBECRYL® 110 is 4°C to 40°C (39°F to 104°F).

- Care should be taken not to expose the product to high temperature conditions, direct sunlight, ignition sources, oxidizing agents, alkalis or acids.

- This might cause uncontrollable polymerization of the product with the generation of heat.

- Storage and handling should be in stainless steel, amber glass, amber polyethylene or baked phenolic lined containers.

- Procedures that remove or displace oxygen from the material should be avoided.

- Do not store this material under an oxygen free atmosphere.

- Dry air is recommended to displace material removed from the container.

Other

- Appearance

- Clear liquid

- Appearance (SDS)

- Liquid

- Color (SDS)

- Yellow

- Item Number

- Odor (SDS)

- Acrylate

- Other Hazards

- Polymerization may occur from excessive heat, contamination or exposure to direct sunlight.

- Protect from Freezing

- Yes

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions Acid Value max. 1.0 mg KOH/g mg KOH/g - Optical Properties

Value Units Test Method / Conditions Color Scale max. 5.0 Gardner Gardner Gardner Color Scale Refractive Index 1.505 - at 20°C, nD - Physical Properties

Value Units Test Method / Conditions Density 1.12 g/mL g/mL At 25°C Flash Point min. 100.0 °C °C Setaflash Molecular Weight 236.0 g/mol g/mol Storage Temperature 39.2-104.0 °F °F Vapor Pressure max. 0.03 mm Hg mm Hg At 20°C Viscosity 13.0-27.0 mPa.s mPa.s At 25°C - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) min. 200.0 °C °C Density (SDS) 1.12 g/cm³ g/cm³ Flash Point (SDS) 187.0 °C °C Vapor Pressure (SDS) 0.04 hPa hPa at 20°C Volatile Content (SDS) max. 0.3 % % - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 0.0 d d