Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Function

- Binder

- Product Code

- MITM00466

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Product Benefits

- Resistance to yellowing upon cure and over time

- Low viscosity

- Good cure response

- Good chemical and solvent resistance

Applications & Uses

- Coating End Applications

- Compatible Substrates & Surfaces

- Cure Method

- Markets

- Applications

- Product Applications

EBECRYL® 893 is recommended for use in UV curable field applied concrete and VCT coatings.

Properties

- Physical Form

Technical Details & Test Data

- Technical Data

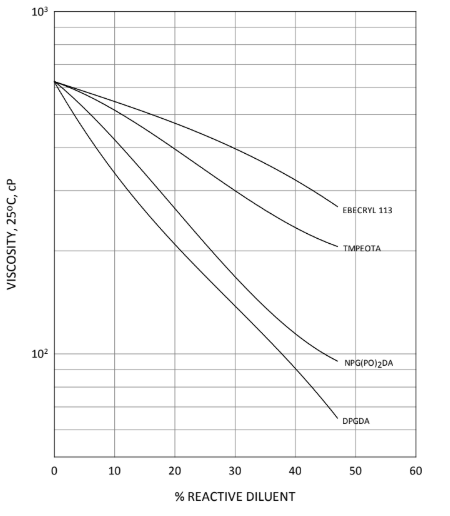

Graph I shows the viscosity reduction of EBECRYL® 893 with several of the recommended diluents for concrete and VCT coatings: dipropylene glycol diacrylate (DPGDA), propoxylated neopentyl glycol diacrylate (NPG(PO)2DA), ethoxylated trimethylolpropane triacrylate (TMPEOTA), and EBECRYL® 113. Although viscosity reduction can be achieved with non-reactive solvents, reactive diluents are preferred because they are essentially 100 percent converted during UV/EB exposure to form a part of the coating or ink, thus reducing solvent emissions. The specific reactive diluents used will influence performance properties such as hardness and flexibility.

Packaging & Availability

Principal Information

- Group Principal Number

- S000001

- Principal

Storage & Handling

- Storage Conditions

- Care should be taken not to expose the product to high temperature conditions, direct sunlight, ignition sources, oxidizing agents, alkalis or acids.

- This might cause uncontrollable polymerization of the product with the generation of heat.

- Storage and handling should be in stainless steel, amber glass, amber polyethylene or baked phenolic lined containers.

- Procedures that remove or displace oxygen from the material should be avoided.

- Do not store this material under an oxygen free atmosphere.

- Dry air is recommended to displace material removed from the container.

- Wash thoroughly after handling.

- Keep container tightly closed.

- Use with adequate ventilation.

Other

- Appearance

- Clear liquid

- Appearance (SDS)

- Liquid

- Color (SDS)

- Clear colorless

- IATA/ICAO Proper Shipping Name

- Environmentally hazardous substance, liquid, N.O.S.

- IATA/ICAO Technical name (N.O.S.)

- Acrylated resin

- IATA/ICAO UN Number

- UN3082

- IMO/IMDG Proper Shipping Name

- Environmentally hazardous substance, liquid, N.O.S.

- IMO/IMDG Technical name (N.O.S.)

- Acrylated resin

- IMO/IMDG UN Number

- UN3082

- Immiscible In (SDS)

- Water

- Item Number

- Odor (SDS)

- Acrylate

- Other Hazards

- Polymerization may occur from excessive heat, contamination or exposure to direct sunlight .

- Protect from Freezing

- Yes

- TDG Canada Proper Shipping Name

- Environmentally hazardous substance, liquid, N.O.S.

- TDG Canada Technical name (N.O.S.)

- Acrylated resin

- TDG Canada UN Number

- UN3082

- Temperature Control

- Yes

- USA/DOT Proper Shipping Name

- Environmentally hazardous substance, liquid, N.O.S.

- USA/DOT Technical name (N.O.S.)

- Acrylated resin

- USA/DOT UN Number

- UN3082

- Material Composition

Value Units Test Method / Conditions Oligomer Content 100.0 %(W/W) %(W/W) - Mechanical Properties

Value Units Test Method / Conditions Elongation at Break 2.7 % % UV cured, 125µm thick films Tensile Modulus 69355.0 psi psi at break, UV cured 125 μ thick films Tensile Strength 1422.0 psi psi at break, UV cured 125 μ thick films - Optical Properties

Value Units Test Method / Conditions Color Scale max. 3.0 Gardner Gardner Gardner Color Scale - Physical Properties

Value Units Test Method / Conditions Density 1.11 g/mL g/mL at 25°C Storage Temperature 39.2-104.0 °F °F Viscosity 600.0 mPa.s mPa.s at 25°C - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Density (SDS) 1.1-1.13 g/cm³ g/cm³ Flash Point (SDS) min. 110.0 °C °C SetaFlash Closed Cup Viscosity (SDS) 2400.0-2800.0 mPa.s mPa.s at 25°C, 10 rpm, low viscous liquid - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 0.0 d d