Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Function

- Binder

- Product Code

- MITM11374

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

- Product Features

Properties of Low Microfoam Emulsions (Coatings Applied at 100°F (38°C) and 25 Relative Humidity)

Emulsion RHOPLEX® CL-204 Acrylic Emulsion Condition Microfoam 13 24 hr dry, (counted under microscope) Bubbles/mm² Print Resistance³ 10 4 hr dry, 1 hour print, 2 psi / 5psi Print Resistance³ 10 4 hr dry, 16 hours print, 2 psi / 5psi Cold Check Resistance Pass 20 Cycles 1 cycle = 1 hour at 6°F

1 hour at 120°F

0.5 hour at RTStain Resistance, 24hr recovery 10 Water (6 and 24 hour spot test) Stain Resistance, 24hr recovery 8 Ethanol (1 and 6 hour spot test) Stain Resistance, 24hr recovery 7 Formula 409 cleaner

(1 and 6 hour spot test)Appearance Good Clarity Appearance Good Grain Definition Coalescents 0.266 pounds on polymer pounds

Butyl CELLOSOLVEᵀᴹ

CoalescentCoalescents 0.085 Butyl CARBITOLᵀᴹ Solvent 2. Measured at 70x magnification where bubbles are clearly visible.

3. Visual scale; 10 = best

Substrates: Stained cherry; unstained maple for cold check only

Sample preparation: conventional spray; 3 coats self-sealed; each coat 1 mil air dry; 30 minute air dry between coats.- Product Benefits

- RHOPLEX® CL-204 Acrylic Emulsion is specifically engineered to minimize this microfoam entrapment by slowing the film-set process which occurs under extreme ambient conditions, while still maintaining acceptable early print resistance properties.

- RHOPLEX® CL-204 Acrylic Emulsion waterborne emulsion coatings achieve both of these formerly exclusive properties: low microfoam entrapment and early print resistance. Note that the ambient conditions during evaluation were among the harshest encountered for waterborne coatings, 100°F (38°C) and 25% relative humidity.

- Another benefit of RHOPLEXTM CL-204 Acrylic Emulsion is that the volatile organic content (VOC) of typically formulated clear topcoat lacquers is less than 2.5 pounds per gallon (less water) or 0.40 pounds of VOC per pound of polymer solids.

Applications & Uses

- Application Area

- Coating End Applications

- Compatible Substrates & Surfaces

- Markets

- Applications

Properties

- Physical Form

- Characteristics of Coalescents

Chemical Type Commercial Designations Volatility BuAc = 100 Solubility, 20°C, Weight% In Water Water In Propylene Glycol n-Butyl Ether PNB 7 6.4 15.5 Ethylene Glycol Monobutyl Ether EB 6 Complete Complete Dipropylene Glycol Methyl Ether DPM 2 Complete Complete Dipropylene Glycol n-Butyl Ether DPnB 0.4 5 12 Diethylene Glycol Monobutyl

EtherDB 0.3 Complete Complete Ester Alcohol Texanol⁴ 0.2 Insoluble 0.9 4. Not recommended as a coalescent with Rhoplex CL-204 but included for comparison purposes.

Technical Details & Test Data

- Technical Information

- Viscosity - The viscosity of the CL-204-1 formulation will increase with pH adjustment as well as with the addition of coalescing aids. The use of ACRYSOL® RM-825 Rheology Modifier is recommended for further viscosity adjustment.

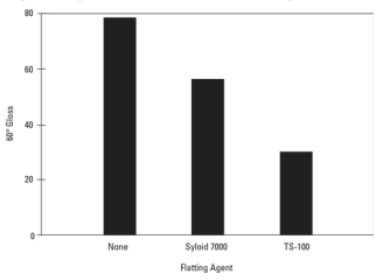

- Flatting Agents - The below figure demonstrates the flatting efficiency of Degussa TS-100 matting agent or Syloid 7000 silica when added at 7% on emulsion solids. Either flatting agent can be used depending on the amount of gloss reduction desired. Coatings based on RHOPLEX® CL-204 Acrylic Emulsion maintain excellent clarity with both of these flatting agents.

Gloss of RHOPLEX® CL-204 Acrylic Emulsion Coatings with Flatting Agents (7% on Emulsion Solids)

- Wetting Agents - To prevent “picture framing” and improve wetting, use Surfynol 104 DPM surfactant at 0.5-1% on formulation solids. Wetting agent should be used sparingly because they can detract from the efficiency of RHOPLEX® CL-204 Acrylic Emulsion in preventing microfoam entrapment.

- Defoamers - Tego Foamex 805 defoamer at 1-2% on polymer solids is recommended for use with RHOPLEX® CL-204 Acrylic Emulsion. For best results, add defoamers after coalescents and under good agitation.

- Mar Aids - The addition of silicone-based mar aids will improve the slip and mar resistance of formulations based on RHOPLEX® CL-204 Acrylic Emulsion. Tego Glide 410 additive should be added at 1-2% solids on resin solids to impart mar and slip resistance. For best results, Tego Glide 410 additive should be reduced to 50% solids with an appropriate solvent (e.g., dipropylene glycol monomethyl ether) for ease of incorporation.

- Waxes - Wax additives can impart mar, slip, and water resistance to the finished coating. Emulsified waxes with the smallest particle size are recommended for clarity. Powdered waxes impart haze to the finished coating due to their large particle size. Michemlube 39235 emulsion is recommended for use in RHOPLEX® CL-204 Acrylic Emulsion formulations.

Safety & Health

- Safety Precautions

- Keep combustible and/or flammable products and their vapors away from heat, sparks, flames and other sources of ignition including static discharge. Processing or operating at temperatures near or above product flashpoint may pose a fire hazard. Use appropriate grounding and bonding techniques to manage static discharge hazards.

- Failure to maintain proper volume level when using immersion heaters can expose tank and solution to excessive heat resulting in a possible combustion hazard, particularly when plastic tanks are used.

- Empty containers may contain hazardous residues. This material and its container must be disposed in a safe and legal manner.

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000005

- Principal

Storage & Handling

- Storage Conditions

Store products in tightly closed original containers at temperatures recommended on the product label.

Other

- Appearance

- Milky white liquid

- Color (SDS)

- White milky

- Item Number

- Odor (SDS)

- Ammonia

- Protect from Freezing

- Yes

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions pH 7.5 - - Material Composition

Value Units Test Method / Conditions Solid Content 43.0 %(W/W) %(W/W) Volatile Organic Compounds (VOC) max. 3.0 g/L g/L - Physical Properties

Value Units Test Method / Conditions Density 8.65 lb/gal lb/gal wet Density 9.15 lb/gal lb/gal Dry Film Forming Temperature 26.0 °C °C Storage Temperature 34.0-120.0 °F °F Viscosity 400.0 cPs cPs - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) 100.0 °C °C Evaporation Rate (SDS) max. 1.0 % % Butyl acetate = 1 Melting Point (SDS) 0.0 °C °C Relative Vapor Density (SDS) max. 1.0 - Air = 1 Specific Gravity (SDS) 1.0-1.2 - Water = 1 Vapor Pressure (SDS) 17.0 mm Hg mm Hg at 20°C Viscosity (SDS) 100.0-500.0 mPa.s mPa.s Volatile Content (SDS) 56.0-58.0 % % Water pH (SDS) 6.5-7.7 - - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 0.0 d d