Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Function

- Binder

- Product Code

- MITM11294

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

- Product Benefits

- Provides ability to formulate high-build coatings for Deck & Concrete Restoration

- 100% Acrylic

- APEO-free*

- Excellent flexibility and crack resistance over well-weathered wood

- Excellent abrasion resistance

- Very good adhesion and blister resistance over well-weathered wood

* - Manufactured without the use of APEO surfactants

- Performance Highlights

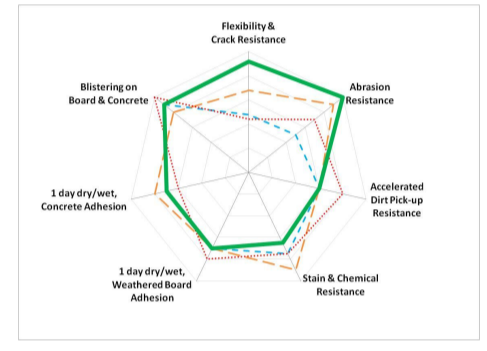

The performance of RHOPLEX® DCR-113 binder in a 43.5% PVC / 43% Volume Solids formulation (tinted to Cedar-tone) is shown in Figure 1 below, in comparison to three commercially-available deck & concrete restoration coating products (also tinted to cedar- tone). The results shown in the figure show how RHOPLEX® DCR-113 binder can provide a solid overall balance of properties required for restoration coatings, highlighted by an excellent combination of flexibility and crack resistance along with resistance to abrasive damage.

Figure – Lab performance properties of RHOPLEX® DCR-113 (—) in Cedar-tone screening formulation (43.5% PVC/43% Volume solids, 50g/L VOC), compared to three commercially-available Deck & Concrete Restoration coatings.

Applications & Uses

- Coating End Applications

- Compatible Substrates & Surfaces

- Markets

- Applications

Properties

- Physical Form

Safety & Health

- Safety Precautions

Empty containers may contain hazardous residues. This material and its container must be disposed in a safe and legal manner.

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000005

- Principal

Storage & Handling

- Storage Conditions

Store products in tightly closed original containers at temperatures recommended on the product label.

Other

- Appearance

- Milky white liquid

- Color (SDS)

- White

- Item Number

- Odor (SDS)

- Ammonia

- Other Hazards

- No data available

- Protect from Freezing

- Yes

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions pH 8.5-9.0 - - Material Composition

Value Units Test Method / Conditions Solid Content 53.5 - - Physical Properties

Value Units Test Method / Conditions Density 9.4 lb/gal lb/gal dry polymer Film Forming Temperature 0.0 °C °C Storage Temperature 34.0-120.0 °F °F Viscosity 500.0 cPs cPs Brookfield Viscometer at 30 rpm, 3 spindle - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) 100.0 °C °C Evaporation Rate (SDS) max. 1.0 % % Butyl acetate = 1 Melting Point (SDS) 0.0 °C °C Relative Vapor Density (SDS) max. 1.0 - Air = 1 Specific Gravity (SDS) 1.0-1.2 - Water = 1 Vapor Pressure (SDS) 17.0 - at 20°C Viscosity (SDS) 100.0-1500.0 - Volatile Content (SDS) 46.0-47.0 % % Water pH (SDS) 8.5-9.5 - - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 0.0 -