Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Country of Origin

- Function

- Binder

- Product Code

- MITM11382

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

- Product Benefits

- State-of-the-arttechnology forhigherperformance

- 100% acrylic ambient crosslinking composition

- Excellent gloss potential

- Excellent early and ultimate block resistance

- Excellent alkyd adhesion

- Outstanding stain removal

- Very good resistance to household chemicals, grease, and hand creams

- Expanded formulation latitude to meet new VOC regulations (50 g/l to 150 g/l VOC)

- Excellent slurry compatibility

Applications & Uses

- Coating End Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Markets

- Applications

Properties

- Physical Form

Technical Details & Test Data

- Technical Data

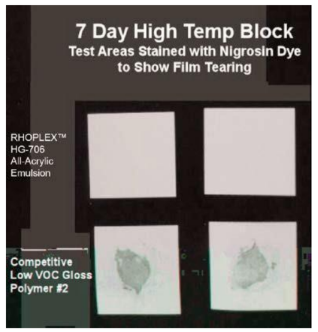

The photo above demonstrates the superior block resistance of HG-706 All-Acrylic Emulsion in a 7-day, high temperature block test. The gloss enamel based on a competitive binder clearly shows tearing of the paint film, while the gloss enamel RHOPLEX™ HG-706 All-Acrylic Emulsion retains its integrity.

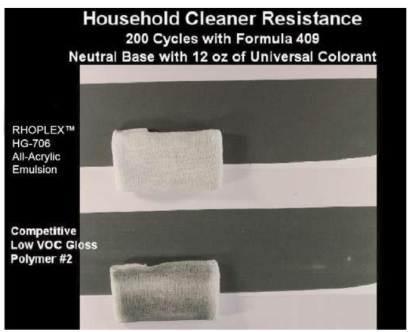

The excellent household chemical resistance of gloss enamels based on RHOPLEX™ RHOPLEX®; HG-706 All-Acrylic Emulsion is demonstrated in the photo above.

The gloss enamel based on a competitive polymer degrades when wiped with a home cleaner, while the enamel based on RHOPLEX™ HG-706 All-Acrylic based on Emulsion stands up to the 200 cleaning cycles.- Technical Data

Ambient Temperature Crosslinking

- RHOPLEX® HG-706 All-Acrylic Emulsion offers the benefits of ambient temperature crosslinking chemistry in a one-pack system.

- It will oxidatively cure after the coalescing of latex particles to form a crosslinked film with improved hardness, toughness, and resistance properties.

- Aqueous gloss enamels based on RHOPLEX® HG-706 All-Acrylic Emulsion will have similar drying characteristics to conventional latex paints.

- They exhibit very good early properties and will continue to improve during the curing process which may require two to four weeks for some properties to fully develop.

- Unlike the traditional oxidative cure of alkyd-based gloss enamels, RHOPLEX® HG-706 All-Acrylic Emulsion will not continue to cure and embrittle over time.

- The final result is a coating with the unique combination of flexibility and toughness.

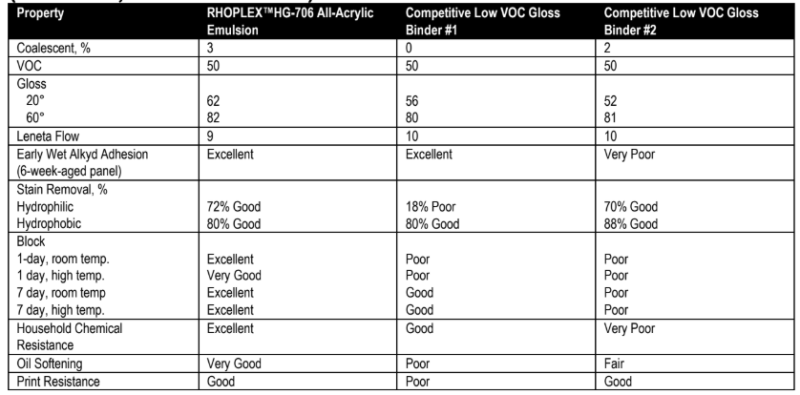

The performance of RHOPLEX® HG-706 All-Acrylic Emulsion is compared to that of two competitive low VOC gloss binders in the following table.(19.4% PVC, 35% Volume Solids)

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000005

- Principal

Storage & Handling

- Handling Information

- Keep combustible and/or flammable products and their vapors away from heat, sparks, flames and other sources of ignition including static discharge.

- Processing or operating at temperatures near or above product flashpoint may pose a fire hazard.

- Use appropriate grounding and bonding techniques to manage static discharge hazards.

- Failure to maintain proper volume level when using immersion heaters can expose tank and solution to excessive heat resulting in a possible combustion hazard, particularly when plastic tanks are used.

- Storage Conditions

Store products in tightly closed original containers at temperatures recommended on the product label.

Other

- Appearance

- Milky white liquid

- Color (SDS)

- White

- Item Number

- Odor (SDS)

- Ammonia

- Protect from Freezing

- Yes

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions pH 8.6-9.1 - - Material Composition

Value Units Test Method / Conditions Solid Content 45.0 % % - Physical Properties

Value Units Test Method / Conditions Bulking Value 0.1045 gal/lb gal/lb dry solids Bulking Value 0.104 gal/lb gal/lb wet Density 8.84 lb/gal lb/gal Film Forming Temperature max. 5.0 °C °C Storage Temperature 34.0-120.0 °F °F Viscosity max. 500.0 cPs cPs Brookfield Viscometer spindle 2, 60 гр - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) 100.0 °C °C Evaporation Rate (SDS) max. 1.0 % % Butyl acetate = 1 Melting Point (SDS) 0.0 °C °C Relative Vapor Density (SDS) max. 1.0 - Air = 1 Specific Gravity (SDS) 1.0-1.2 - Water = 1 Vapor Pressure (SDS) 17.0 mm Hg mm Hg at 20°C Viscosity (SDS) 5.0-125.0 mPa.s mPa.s Volatile Content (SDS) 54.0-56.0 % % Water pH (SDS) 8.6-9.1 - - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 300.0 d d