Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Chemical Name

- Country of Origin

- Function

- Resin, Monomer

- Plastics & Elastomers Functions

- Product Code

- MITM13438

- Single Ingredient

- Yes

- Synonyms

- 2-Ethyl-2(hydroxymethyl)-1,3-propanediol trimethacrylate, TMPT

- Technologies

- Product Families

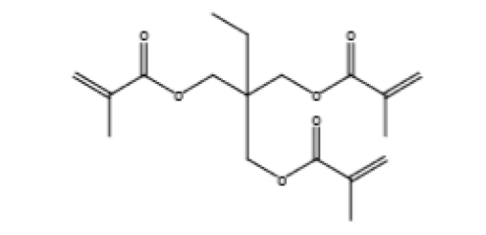

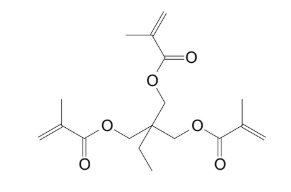

- Chemical Structure

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Materials Features

- Performance Highlights

EBECRYL® TMPTMA is characterized by:

- Low color

- Low viscosity

- Low volatility

UV/EB curable formulated products containing EBECRYL® TMPTMA are characterized by:

- High crosslink density

- Chemical resistance

- Hardness

- High tensile strength

- Thermal resistance

The actual properties of cured products also depend on the selection of other formulation components such as co-reactants, additives and initiators.

Applications & Uses

- Adhesive & Sealant End Applications

- Applicable Processes

- Coating End Applications

- Compatible Polymers & Resins

- Cure Method

- Plastics & Elastomers End Uses

- Product Applications

- Elastomer and Rubber: co-agent for peroxide curing system.

- Plastic and Polymer: cross-linking agent for free radical polymerization systems.

- Adhesives

- Sealant

- Product Applications

EBECRYL® TMPTMA can provide improved properties to polymers used in:

- Rubber crosslinking

- Concrete crack repair

- Anerobic and structural adhesives

Properties

- Physical Form

- Soluble In

Packaging & Availability

Principal Information

- Group Principal Number

- S000001

- Principal

Storage & Handling

- Storage Conditions

- Care should be taken not to expose radiation curable products to temperatures exceeding 40°C for prolonged periods or to direct sunlight.

- This might cause uncontrollable polymerization of the product with generation of heat.

- Storage and handling should be in stainless steel, amber glass, amber polyethylene or baked phenolic lined containers.

- Do not store this material under an oxygen free atmosphere. Use dry air to displace material removed from the container.

- EBECRYL® TMPTMA should not be stored for more than 2 years.

- Storage Conditions

Care should be taken not to expose the product to high temperature conditions, direct sunlight, ignition sources, oxidizing agents, alkalis or acids. This might cause uncontrollable polymerization of the product with the generation of heat. Storage and handling should be in stainless steel, amber glass, amber polyethylene or baked phenolic lined containers. Procedures that remove or displace oxygen from the material should be avoided. Do not store this material under an oxygen free atmosphere. Dry air is recommended to displace material removed from the container. Wash thoroughly after handling. Keep container tightly closed. Use with adequate ventilation.

Other

- Appearance

- Clear liquid

- Appearance (SDS)

- Liquid

- Color (SDS)

- Clear colorless to pale yellow

- IATA/ICAO Proper Shipping Name

- Environmentally hazardous substance, liquid, N.O.S.

- IATA/ICAO Technical name (N.O.S.)

- Trimethylolpropane trimethacrylate esters

- IATA/ICAO UN Number

- UN3082

- IMO/IMDG Proper Shipping Name

- Environmentally hazardous substance, liquid, N.O.S.

- IMO/IMDG Technical name (N.O.S.)

- Trimethylolpropane trimethacrylate esters

- IMO/IMDG UN Number

- UN3082

- Item Number

- Odor (SDS)

- Ester acrylate

- Other Hazards

- Polymerization may occur from excessive heat, contamination or exposure to direct sunlight, Contact with skin may cause a cross-allergic reaction in persons already sensitized to acrylates.

- Protect from Freezing

- Yes

- TDG Canada Proper Shipping Name

- Environmentally hazardous substance, liquid, N.O.S.

- TDG Canada Technical name (N.O.S.)

- Trimethylolpropane trimethacrylate esters

- TDG Canada UN Number

- UN3082

- Temperature Control

- Yes

- USA/DOT Proper Shipping Name

- Environmentally hazardous substance, liquid, N.O.S.

- USA/DOT Technical name (N.O.S.)

- Trimethylolpropane trimethacrylate esters

- USA/DOT UN Number

- UN3082

- Chemical Properties

Value Units Test Method / Conditions Acid Value max. 1.0 mg KOH/g mg KOH/g Functionality 3.0 - Methoxyhydroquinone Content 100.0-300.0 ppm ppm Monomethyl ether, hydroquinone - Material Composition

Value Units Test Method / Conditions Acid Content max. 1.0 % % Methyl Hydroquinone Content 100.0-300.0 ppm ppm as stabilizer Residual Solvent Content max. 0.1 % % - Optical Properties

Value Units Test Method / Conditions Color Scale max. 100.0 APHA APHA Refractive Index 1.472 - at 20°C - Physical Properties

Value Units Test Method / Conditions Density 1.07 g/mL g/mL at 25°C Density 1.07 g/cm³ g/cm³ at 20°C Flash Point min. 100.0 °C °C Setaflash Moisture Content max. 0.1 %(W/W) %(W/W) Molecular Weight 338.0 Da Da Storage Temperature 39.2-104.0 °F °F Viscosity 40.0-70.0 cPs cPs at 25°C - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Autoignition Temperature (SDS) 350.0 °C °C Boiling Point (SDS) min. 200.0 °C °C Density (SDS) 1.07-1.09 g/cm³ g/cm³ Flash Point (SDS) 177.0 °C °C Pensky-Martens Closed Cup (PMCC) Partition coefficient n-octanol/water (SDS) 4.1 - OECD 117 at 25°C Solubility In Water (SDS) 20.0 mg/L mg/L at 20°C Vapor Pressure (SDS) max. 0.003 hPa hPa at 20°C Viscosity (SDS) 50.0-70.0 mPa.s mPa.s at 25°C, low viscous liquid Volatile Content (SDS) max. 0.1 %(W/W) %(W/W) - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 730.0 d d