Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Chemical Family

- Country of Origin

- Function

- Deaerator, Defoamer

- Product Code

- MITM15790

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

- Benefits

- Suitable for pigmented formulations

- Solvent-free

- Outstanding performance in higher viscosity formulations

Applications & Uses

- Application Method

- Coating End Applications

- Cure Method

- Ink & Toner End Applications

- Markets

- Applications

- Applications

- Screen Inks

- Floor coatings

- Protective coatings

- High solid industrial coatings

- Processing Information

- The product mayshow post-thickening during storage. This does not affect the performance properties.

- Stir before use!

- Add before grinding.

- Additive must be incorporated with sufficiently high shear.

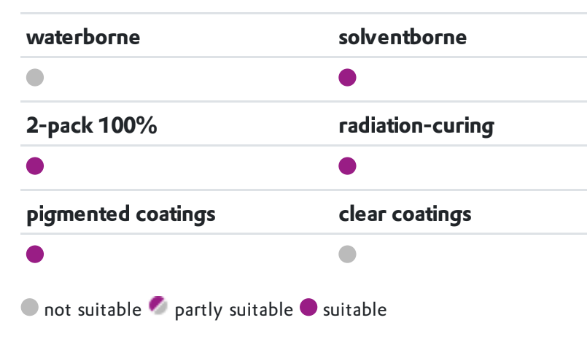

- Product Suitability

- Dosage Information

As supplied calculated on total formulation: 0.05 - 1.0 %

Properties

- Physical Form

- Soluble In

Packaging & Availability

Principal Information

- Group Principal Number

- S000006

- Principal

Storage & Handling

- Storage and Handling Conditions

When stored in an original unopened packaging between -40 and +40 °C, the product has a shelf life of at least 24 months from the date of manufacture.

Other

- Appearance

- Turbid liquid

- Color (SDS)

- Colorless, cloudy

- Insoluble in (SDS)

- Water

- Item Number

- Odor (SDS)

- Odorless

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Application Information

Value Units Test Method / Conditions Dosage (Use Level) 0.05-1.0 % % - Material Composition

Value Units Test Method / Conditions Active Content 100.0 % % - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Density (SDS) 0.96-1.0 g/cm³ g/cm³ at 25°C Flash Point (SDS) min. 212.0 °F °F Kinematic Viscosity (SDS) 120.0-180.0 mm²/s mm²/s at 25°C Viscosity (SDS) 120.0-180.0 mPa.s mPa.s at 25°C - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 24.0 mo mo