Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Chemical Name

- EC Number

- 682-395-5

- Product Code

- MITM09694

- Single Ingredient

- Yes

- Technologies

- Product Families

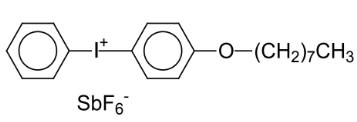

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Product Performance

UVACURE® 1600 is characterized by:

- Finely divided, crystalline powder

- Excellent solubility in epoxy resin systems.

UV cured products containing UVACURE® 1600 are generally characterized by the following performance properties:

- No oxygen inhibition for UV cure

- Low shrinkage on curing

- Excellent adhesion to metals and plastics

- High gloss

- Resistance to yellowing

- Excellent electrical properties

The actual properties of UV/EB cured products also depend on the selection of other formulation components such as co-reactants, additives and photoinitiators.

Applications & Uses

- Coating End Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Cure Method

- Markets

- Applications

- Product Uses

- The recommended level of UVACURE® 1600 is 1-3% in clear coatings. The use of a sensitizer such as isopropylthioxanthone (ITX) or anthracene, and/or higher levels of UVACURE® 1600 may be required in pigmented systems.

- UVACURE® 1600 can be blended with liquid UV cationic curable materials (epoxides, hydroxy functional materials, vinyl ethers) by simple mixing. Heating is not normally required.

- Typically, UV cationic systems will be tack free within seconds after UV exposure. However, the UV energy level, formula composition, temperature, and relative humidity will influence this tack free time. UV cationic systems continue to polymerize after UV exposure, and full properties may not develop until several hours afterwards. This post UV curing will take place under ambient conditions, but can be accelerated with heat (65-200°C for 5-30 minutes). The application of heat immediately prior to UV exposure can allow faster line speeds and/or lower UV dose levels, and can mitigate the effects of high relative humidity.

- Product Applications

UV cured coatings formulated with UVACURE® 1600 can be used for:

- Metal coatings

- Overprint varnishes

- Plastic coatings

- Photoresists

Properties

- Physical Form

- Soluble In

Packaging & Availability

Principal Information

- Group Principal Number

- S000001

- Principal

Storage & Handling

- Storage Conditions

- Care should be taken not to expose the product to sunlight, ignition sources, oxidizing agents, alkalis or acids. Storage and handling should be in stainless steel, amber glass, amber polyethylene or baked phenolic lined containers. Wash thoroughly after handling. Keep container tightly closed. Use with adequate ventilation.

- UVACURE® 1600 is thermally stable up to approximately 100°C for short periods of time.

Other

- Appearance

- White to tan powder

- Appearance (SDS)

- Solid

- Color (SDS)

- Off white to tan

- Insoluble in (SDS)

- Water

- Item Number

- Odor (SDS)

- Odorless

- Other Hazards

- Not applicable

- USA/DOT UN Number

- Not Applicable

- Application Information

Value Units Test Method / Conditions Dosage (Use Level) 1.0-3.0 % % clear coatings - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Melting Point (SDS) 57.0-58.0 °C °C