Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- CI Number

- Chemical Family

- Chemical Name

- Country of Origin

- Function

- Filler, Pigment

- Industrial Additives Functions

- Pigment Type

- Plastics & Elastomers Functions

- Product Code

- MITM13830

- Single Ingredient

- Yes

- Synonyms

- Barium sulphate, Barium white, BaSO4, E 340, Liquibarine, Micropaque

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Industrial Additives Features

- Labeling Claims

- Materials Features

Applications & Uses

- Applicable Processes

- Coating End Applications

- Industrial Additives End Use

- Plastics & Elastomers End Uses

- Markets

- Applications

- Product Uses

Coatings Fillers Automotive Primers Plastics Automotive Topcoats Ceramics High Gloss Enamel Friction Materials

Powder Coatings Rubber Goods Semi-Gloss Latexes Plastisols Gloss Latexes Adhesives Industrial Coatings Latex Products Architectural Coatings Urethane Foams

Maintenance Coatings Acoustical Compounds

Industrial Primers Insulating Materials

Sound Attenuation Products

Properties

Technical Details & Test Data

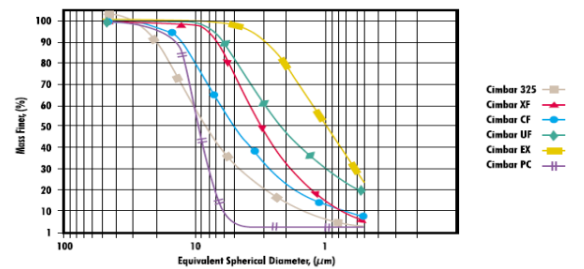

- Particle Size Distribution

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S002777

- Principal

Other

- Appearance (SDS)

- Solid, beige to white

- Insoluble in (SDS)

- Water

- Item Number

- Odor (SDS)

- Odorless

- Other Hazards

- None known

- Temperature Control

- No

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions Loss on Ignition 0.75 % % by Water pH 7.5-9.5 - - Material Composition

Value Units Test Method / Conditions Aluminum Oxide Content 0.01 % % Barium Sulfate Content 98.0-99.0 % % Ferric Oxide Content 0.02 % % Silica Content max. 0.6 % % Total Heavy Metals Content 0.05 % % - Optical Properties

Value Units Test Method / Conditions Brightness 93.0-95.0 % % Hunter "L" Color Scale 93.0 CIELAB CIELAB delta l Refractive Index 1.6 - - Physical Properties

Value Units Test Method / Conditions Bulk Density 145.0 lb/ft³ lb/ft³ Compacted Bulking Value 0.0279 lb/gal lb/gal Density 268.0 lb/ft³ lb/ft³ Hegman Fineness 4.5 - Loose Bulk Density 100.0 lb/ft³ lb/ft³ dry, apparent Particle Size 40.0 µm µm Effective Top Size Sieve Fractionation (Retained) 0.1 % % 325 mesh Specific Gravity 4.4 - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Hardness (SDS) 2.5-3.5 moh moh Specific Gravity (SDS) 4.0-4.3 - Volatile Organic Compounds (VOC) (SDS) 0.0 % % Directive 1999/13/EC pH (SDS) 8.0-10.0 - 10% aqueous slurry - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 1825.0 d d