Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Country of Origin

- Function

- Binder

- Product Code

- MITM11377

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Product Features

- Excellent early sandability

- Early block resistance

- Good hot print resistance

- Outstanding mar and scratch resistance

- Very good non-yellowing properties, especially over white finishes

Applications & Uses

- Application Area

- Coating End Applications

- Compatible Substrates & Surfaces

- Markets

- Applications

Properties

- Physical Form

Technical Details & Test Data

- Technical Data

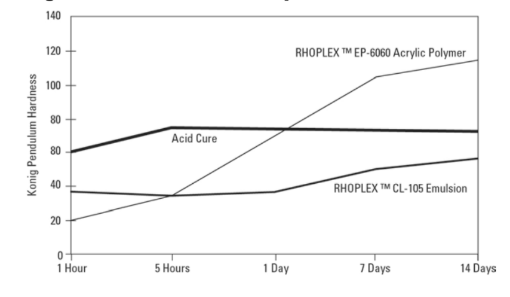

Hardness Development as a Function of Drying Time of the Coating

Appearance:

- The clarity and grain definition of clear lacquers based on RHOPLEX® EP-6060 Acrylic

- Polymer are good. The best appearance is achieved on light wood.

- Since RHOPLEX® EP-6060 Acrylic Polymer is delivered at a pH between 7.9 and 8.9, discoloration may occur over oak.

- It is recommended, therefore, that a sealer based on RHOPLEX® CL-105 Acrylic Polymer be used on oak before applying a lacquer based on RHOPLEX® EP-6060 Acrylic Polymer.

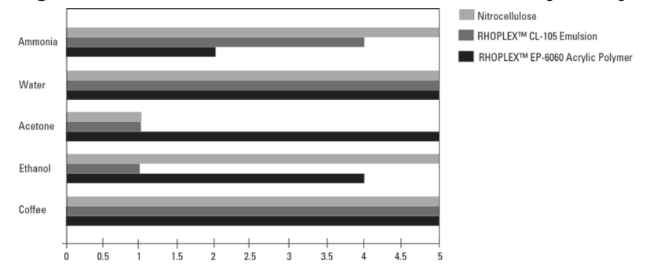

Stain Resistance:

- The stain resistance of topcoats based on RHOPLEX® EP-6060 Acrylic Polymer is comparable to that of nitrocellulose lacquers.

- The use of RHOPLEX® EP-6060 Acrylic Polymer for topcoat applications (such as table tops) that are normally cleaned with high pH cleaning agents is not recommended.

- The stain resistance of RHOPLEX® EP-6060Acrylic Polymer is illustrated in Figure 2 below.

Stain Resistance Test Specifications:

- RHOPLEX® EP-6060 Acrylic Polymer-based lacquers were sprayed on pine panels (4-5 mils wet film) and dried for 10 minutes at 22oC and 55% relative humidity.

- The lacquers were then dried in an oven for 10 minutes at 60°C.

- After cooling for five minutes, the panels were sanded and a second coat of 4-5 wet mils was applied.

- Stains were evaluated after two weeks drying of the coating.

- Stains sat on the coating for the following lengths of time:

- ammonia for two minutes; water for 24 hours; acetone for two minutes; ethanol for six hours, and coffee for six hours.

Stain Resistance of RHOPLEX® EP-6060 Acrylic Polymer

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000005

- Principal

Storage & Handling

- Handling Information

- Keep combustible and/or flammable products and their vapors away from heat, sparks, flames and other sources of ignition including static discharge.

- Processing or operating at temperatures near or above product flashpoint may pose a fire hazard.

- Use appropriate grounding and bonding techniques to manage static discharge hazards.

- Failure to maintain proper volume level when using immersion heaters can expose tank and solution to excessive heat resulting in a possible combustion hazard, particularly when plastic tanks are used.

- Storage Conditions

Store products in tightly closed original containers at temperatures recommended on the product label.

Other

- Appearance

- Milky white liquid

- Color (SDS)

- White

- Item Number

- Odor (SDS)

- Ammonia

- Other Hazards

- No data available

- Protect from Freezing

- Yes

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions Acid Value 104.0 mg KOH/g mg KOH/g solid resin pH 7.9-8.9 - - Material Composition

Value Units Test Method / Conditions Solid Content 37.5-38.5 % % - Physical Properties

Value Units Test Method / Conditions Film Forming Temperature 58.0 °C °C Specific Gravity 1.07 - Storage Temperature 34.0-120.0 °F °F Viscosity max. 1000.0 cPs cPs Brookfield Viscometer at 25°C, LVF, spindle 4, 60 rpm - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) 100.0 °C °C Evaporation Rate (SDS) max. 1.0 % % Butyl acetate = 1 Melting Point (SDS) 0.0 °C °C Relative Vapor Density (SDS) max. 1.0 - Air = 1 Specific Gravity (SDS) 1.0-1.2 - Water = 1 Vapor Pressure (SDS) 17.0 - at 20°C Viscosity (SDS) max. 100.0 - Volatile Content (SDS) 61.0-63.0 % % pH (SDS) 7.9-8.9 - - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 0.0 -