Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Country of Origin

- Function

- Binder & Resin, Crosslinking Agent

- Product Code

- MITM11253

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

- Product Benefits

- 100% acrylic composition

- Unique ambient crosslinking technology provides:

- Excellent tannin, marker, water, and nicotine stain blocking

- Enhanced adhesion to a variety of repaint and new substrates

- Wide formulation latitude provides performance at high PVC

- Excellent flash rust and nail head rust resistance

- Excellent exterior crack resistance over dimensionally unstable substrates and weathered wood

- Good zinc oxide stability

- Low VOC

Applications & Uses

- Coating End Applications

- Compatible Substrates & Surfaces

- Markets

- Applications

Properties

- Physical Form

Technical Details & Test Data

- Technical Data

Exterior Durability

With over five years of exterior exposure data, the all-acrylic composition ofRHOPLEX® PR-33 Emulsion Polymer provides excellent exterior durability in primer formulations.

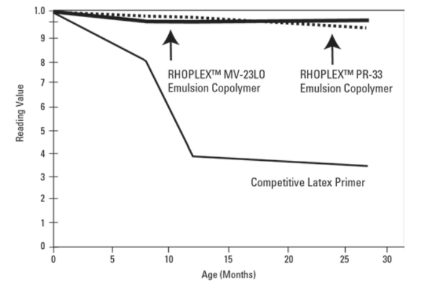

Figure 1 shows the outstanding crack resistance, over weathered white pine, of a primer based on RHOPLEX® PR-33 Emulsion Polymer.Crack Resistance of Primers on 3-Month Weathered White Pine Exposed at South 45

Exterior Resistance Properties

Table 1 displays the excellent exterior tannin stain blocking, rust resistance and blistering characteristics of RHOPLEX® PR-33 Emulsion Polymer versus a competitive latex vehicle and a self-primed topcoat.Table 1: Exterior Performance Comparison of Partners 6 Months Exposure (00AJ)

RHOPLEX®; PR-33 Emulsion

Polymer

Primer 31PVC/35VSCompetitive Latex Primer

31PVC/35VSSelf Primed Topcoat

Tannin Stain Blocking 8 6 3 Nail Head Rust Resistance 9 6 4 Rust Staining Cold Rolled Steel 10 8 1 Blistering on Unspangled Galvanized 10 1 5 Enhanced Adhesion

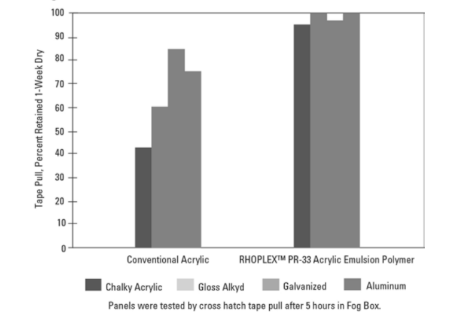

Figure 2 shows the enhanced wet adhesion of RHOPLEX® PR-33 Emulsion Polymer, over a variety of substrates, compared to a conventional acrylic primer. The primers were tested in a 31 PVC/35 VS formulation after one week dry at 25°C and 50% RH. The primers were placed in a streaming fog box for five hours prior to testing.Figure 2: Wet Adhesion of RHOPLEX® PR-33 Emulsion Polymer

Another area where RHOPLEX® PR-33 Emulsion Polymer excels in stain blocking performance is over many common household stains.

Table 3 shows the comparative stain blocking performance of RHOPLEX® PR-33 Emulsion Polymer over a variety of difficult household stains. These stains include nicotine, water, tannin, grape juice, coffee and lipstick.Household Stain Blocking Performance

Stain Type RHOPLEX® PR-33 Emulsion

Polymer

Primer 31PVC/35VSCompetitive Latex Primer

31PVC/35VSRHOPLEX® PR-3232LO Primer

31PVC/35VSNicotine Stained Vinyl Chart¹ 8 6 7 Water Damaged Ceiling Tile² 6 4 6 Tannin Stain Block Cedar³ 8 5 6 Tannin Stain Block Redwood³ 6 3 4 Grape Juice¹ 8 7 7 Coffee¹ 6 5 5 Lipstick¹ 9 8 7 Ratings: 10 = Best, no visible stain 0 = Complete bleen through

¹ One coat of primer applied via drawdown and allowed to dry 2 hours. One application of flat PVA topcoat.

² Two coats of respective primer and one application of flat PVA topcoat. One hour to dry between coats.

³ Primer applied at 350 ft²/gal., dry 4 hours, topcoat with G-08-2 exterior acrylic semigloss.

Safety & Health

- Safety Precautions

Based on similar materials, this product is not expected to be toxic via single acute oral or dermal exposure. It may be a mild to moderate skin and eye irritant.

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000005

- Principal

Other

- Appearance

- Milky white liquid

- Color (SDS)

- Light yellow

- Item Number

- Odor (SDS)

- Ammonia

- Protect from Freezing

- Yes

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions pH 8.5-9.5 - - Material Composition

Value Units Test Method / Conditions Solid Content 43.0 % % - Physical Properties

Value Units Test Method / Conditions Bulking Value 0.1037 gal/lb gal/lb dry solids Bulking Value 0.113 gal/lb gal/lb wet Density 8.85 g/cm³ g/cm³ Film Forming Temperature 6.0 °C °C Storage Temperature 34.0-120.0 °F °F Viscosity 50.0-1000.0 cPs cPs Brookfield Viscometer - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) 100.0 °C °C Evaporation Rate (SDS) max. 1.0 % % Melting Point (SDS) 0.0 °C °C Relative Vapor Density (SDS) max. 1.0 - Specific Gravity (SDS) 1.0-1.2 - Vapor Pressure (SDS) 17.0 mm Hg mm Hg at 20°C Viscosity (SDS) 10.0-300.0 mPa.s mPa.s Volatile Content (SDS) 55.0-58.0 % % pH (SDS) 8.5-9.5 - - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 540.0 d d