Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Country of Origin

- Function

- Oligomer, Monomer

- Product Code

- MITM00386

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Performance Highlights

- EBECRYL® 3605 is characterized by :

- Both epoxy and acrylate functionalities

- Good cure response

- UV/EB cured products based on EBECRYL® 3605 are characterized by the following performance properties :

- High gloss finish

- Good solvent resistance

- Good adhesion to metals and other non-porous substrates

- Improved flexibility over other epoxy acrylates

- The actual properties of UV/EB cured products also depend on the selection of the other formulation components, such as reactive diluent(s), additives and photo-initiators.

- EBECRYL® 3605 is characterized by :

Applications & Uses

- Application Method

- Coating End Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Cure Method

- Markets

- Applications

- Product Application

- Formulated UV/EB curable products containing EBECRYL® 3605 may be applied by lithographic, screen, gravure, direct or reverse roll, and curtain coating methods.

- EBECRYL® 3605 is recommended for use in :

- Coatings and inks for metal substrates including aluminum

- Applications where portions of the curable material are in "shadow" areas

- Applications where thermal post-curing will enhance coating properties

Properties

- Physical Form

Technical Details & Test Data

- Viscosity Reduction

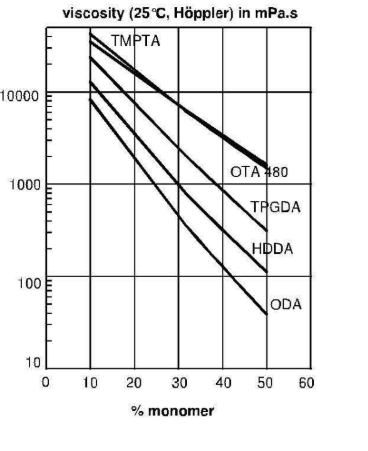

- Ebecryl®3605 can be diluted with reactive monomers such as 1,6 hexanediol diacrylate (HDDA)², trimethylolpropane triacrylate (TMPTA)², tripropyleneglycol diacrylate (TPGDA)², oligotriacrylate (OTA 480)² and octyl/decyl acrylate (ODA)².

- The specific reactive diluent(s) used will influence performance properties such as hardness and flexibility.

- ² HDDA, TMPTA, TPGDA, OTA 480 and ODA are produced by Allnex.

- Technical Data

The graph shows the viscosity reduction of Ebecryl®3605 as a function of the concentration of different monomers.

Safety & Health

- Safety Precautions

- The toxicological properties of this material have not been fully determined.

- Products of this type can be expected to be eye and skin irritants and have the potential to cause sensitization or other allergic responses.

- Appropriate precautions should be taken to avoid eye and skin contact and to avoid inhalation of the aerosols or vapors.

Packaging & Availability

Principal Information

- Group Principal Number

- S000001

- Principal

Storage & Handling

- Storage and Handling Conditions

- Care should be taken not to expose radiation curable products to temperatures exceeding 40℃ for prolonged periods or to direct sunlight.

- This might cause uncontrollable polymerization of the product with generation of heat.

- Storage and handling should be in stainless steel, amber glass, amber polyethylene or baked phenolic lined containers.

- Do not store this material under an oxygen free atmosphere.

- Use dry air to displace material removed from the container.

- This material should not be stored for more than 2 years.

Other

- Appearance (SDS)

- Liquid

- Color (SDS)

- Clear to light yellow

- IATA/ICAO Proper Shipping Name

- Environmentally hazardous substance, liquid, N.O.S.

- IATA/ICAO Technical name (N.O.S.)

- Epoxy acrylate

- IATA/ICAO UN Number

- UN3082

- IMO/IMDG Proper Shipping Name

- Environmentally hazardous substance, liquid, N.O.S.

- IMO/IMDG Technical name (N.O.S.)

- Epoxy acrylate

- IMO/IMDG UN Number

- UN3082

- Insoluble in (SDS)

- Water

- Item Number

- Odor (SDS)

- Acrylate

- Other Hazards

- Polymerization may occur from excessive heat, contamination or exposure to direct sunlight .

- Protect from Freezing

- Yes

- TDG Canada Proper Shipping Name

- Environmentally hazardous substance, liquid, N.O.S.

- TDG Canada Technical name (N.O.S.)

- Epoxy acrylate

- TDG Canada UN Number

- UN3082

- Temperature Control

- Yes

- USA/DOT Proper Shipping Name

- Environmentally hazardous substance, liquid, N.O.S.

- USA/DOT Technical name (N.O.S.)

- Epoxy acrylate

- USA/DOT UN Number

- UN3082

- Chemical Properties

Value Units Test Method / Conditions Acid Value max. 1.0 mg KOH/g mg KOH/g Epoxide Equivalent Weight 450.0 g/eq g/eq - Material Composition

Value Units Test Method / Conditions Solid Content 100.0 %(W/W) %(W/W) - Mechanical Properties

Value Units Test Method / Conditions Tensile Elongation 35.0 % % measured on a 125μ UV cured film Tensile Strength 26.0 MPa MPa measured on a 125μ UV cured film - Optical Properties

Value Units Test Method / Conditions Color Scale max. 5.0 Gardner Gardner Gardner Color Scale - Physical Properties

Value Units Test Method / Conditions Density 1.12 g/cm³ g/cm³ Glass Transition Temperature (Tg) 43.0 °C °C measured on a 125μ UV cured film Molecular Weight 450.0 g/mol g/mol Storage Temperature 39.0-104.0 °F °F Viscosity -1100.0-1100.0 mPa.s mPa.s at 60°C - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) min. 100.0 °C °C Density (SDS) 1.14 g/cm³ g/cm³ Vapor Pressure (SDS) 0.013 hPa hPa at 20°C Viscosity (SDS) 500.0-800.0 mPa.s mPa.s at 18°C - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 2.0 yr yr