Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Function

- Binder

- Product Code

- MITM00455

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Performance Highlights

EBECRYL® 8702 is characterized by:

- Light color

- Low odor

- Fast cure response

- Good pigment wetting

UV/EB cured products containing EBECRYL® 8702 are characterized by the following performance properties:

- Good toughness

- Excellent abrasion and stain resistance

- Impact resistance

- Non-yellowing

- Good exterior durability

The actual properties of UV/EB cured products also depend on the selection of other formulation components such as reactive diluents, additives and photoinitiators.

Applications & Uses

- Application Method

- Coating End Applications

- Compatible Substrates & Surfaces

- Cure Method

- Ink & Toner End Applications

- Markets

- Applications

- Product Applications

Formulated UV/EB curable products containing EBECRYL 8702 may be applied via direct or reverse roll, offset gravure, metering rod, slot die, knife over roll, air knife, curtain, immersion and spin coating methods, as well as screen printing.

EBECRYL® 8702 is recommended for use in:- Automotive OEM or Refinish

- Coatings for wood

- Plastic coatings

- Screen inks

- Light stable coatings

- Metal coatings

Properties

- Physical Form

Technical Details & Test Data

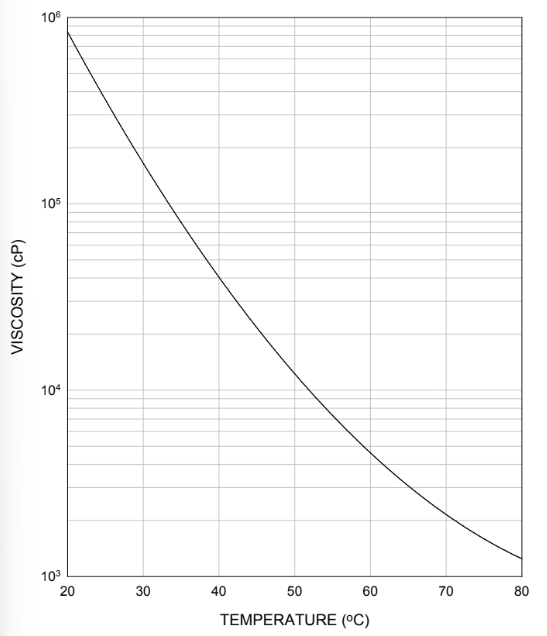

- Viscosity vs Temperature

EBECRYL® 8702 - Viscosity vs. Temperature:

Graph illustrates the change in viscosity of EBECRYL® 8702 with increasing temperature.

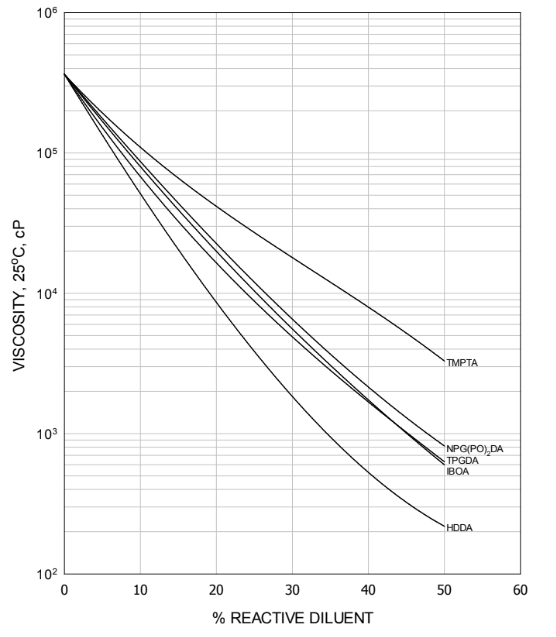

- Viscosity vs Percentage Reactive Diluent

EBECRYL® 8702 - Viscosity Reduction With Reactive Diluents:

- Graph shows the viscosity reduction of EBECRYL® 8702 with 1,6-hexanediol diacrylate (HDDA), isobornyl acrylate (IBOA), neopentyl glycol propoxylate diacrylate (NPG(PO)2DA trimethylolpropane triacrylate (TMPTA), and tripropylene glycol diacrylate (TPGDA).

- Although viscosity reduction can be achieved with non-reactive solvents, reactive diluents are preferred because they are essentially 100 percent converted during UV/EB exposure to form a part of the coating or ink, thus reducing solvent emissions.

- The specific reactive diluents used will influence performance properties such as hardness and flexibility.

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000001

- Principal

Storage & Handling

- Storage Conditions

- Care should be taken not to expose the product to high temperature conditions, direct sunlight, ignition sources, oxidizing agents, alkalis or acids.

- This might cause uncontrollable polymerization of the product with the generation of heat.

- Storage and handling should be in stainless steel, amber glass, amber polyethylene or baked phenolic lined containers.

- Procedures that remove or displace oxygen from the material should be avoided.

- Do not store this material under an oxygen free atmosphere.

- Dry air is recommended to displace material removed from the container.

- Wash thoroughly after handling.

- Keep container tightly closed.

- Use with adequate ventilation.

Other

- Appearance

- Clear liquid

- Appearance (SDS)

- Liquid

- Color (SDS)

- Clear to hazy light yellow

- Insoluble in (SDS)

- Water

- Item Number

- Odor (SDS)

- Acrylate

- Other Hazards

- Polymerization may occur from excessive heat, contamination or exposure to direct sunlight, Contact with skin may cause a cross-allergic reaction in persons already sensitized to acrylates.

- Protect from Freezing

- Yes

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Material Composition

Value Units Test Method / Conditions Isocyanate Content max. 0.2 % % Oligomer Content 100.0 - - Mechanical Properties

Value Units Test Method / Conditions Elongation 10.0 - at break, UV cured 125µm thick films Tensile Modulus 180000.0 psi psi UV cured 125 μm thick films Tensile Strength 4700.0 psi psi UV cured 125 μm thick films - Optical Properties

Value Units Test Method / Conditions Color Scale max. 1.0 Gardner Gardner Gardner Color Scale - Physical Properties

Value Units Test Method / Conditions Density 1.13 g/mL g/mL At 25°C Glass Transition Temperature (Tg) 28.0 °C °C Dynamic Mechanical Analysis (DMA) UV cured 125 μm thick films Storage Temperature 68.0-104.0 °F °F Viscosity 4800.0-6800.0 - At 60°C - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Density (SDS) 1.11 g/cm³ g/cm³ Flash Point (SDS) min. 100.0 °C °C Vapor Pressure (SDS) max. 0.133 - Viscosity (SDS) 3830.0 - At 60°C - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 0.0 -