Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Country of Origin

- Function

- Binder

- Product Code

- MITM11279

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

- Key Features

- Excellent corrosion resistance

- High gloss potential and excellent gloss retention

- Single acrylic resin that can be formulated for primer, midcoat, topcoat, or direct-to-metal applications. Provides a high performance system approach with a single resin

- Low coalescent demand, allowing compliance with stringent VOC regulations, formulations at 100 g/L or less provide excellent performance with the added benefit of freeze-thaw resistance

- Ambient self-crosslinking, providing excellent durability, dirt pickup resistance and solvent/chemical resistance

- Free of APEO-containing surfactants

- Excellent adhesion to various metal substrates (for example, steel, galvanized, aluminum) and other coatings (for example, alkyds)

Applications & Uses

- Application Area

- Coating End Applications

- Compatible Substrates & Surfaces

- Markets

- Applications

- Product Applications

- Industrial Maintenance Finishes—for example, steel structures, tanks, bridges, piping

- Commercial Architectural Finishes for Metal—for example, metal buildings, beams,doors, ceilings

- Institutional Coatings

- DIY Metal Coatings

- Transportation—for example, railcars, shipping containers, truck chassis

Properties

- Physical Form

- Note

(¹)Dirt pickup resistance (DPUR) is measured by an accelerated method employing a simulated dirt slurry (brown iron oxide) applied to the paint surface for a prescribed time, then washing with water and wiping with cheesecloth. The ratio of initial to final Y-reflectance is used as a measure of DPUR. As a reference, MAINCOTE™ HG-54D Resin gives a ratio of 0.91 after a 1 week air cure.

Technical Details & Test Data

- Technical Data

Technology Behind the Benefits

- The benefits observed with coatings based on AVANSE™ MV-100 Resin are partly due to its unique role in the film formation process. With a conventional acrylic latex polymer, the final

- paint film rarely displays an optimum distribution of pigment and extender particles throughout the film.

- Both in the wet state and as the film is drying, pigment and extender particles can aggregate together and form larger agglomerates.

- Keeping the pigment particles separated in the wet state is really the function of dispersants and surfactants.

- Non-optimal dispersion leads to lower gloss and worse barrier properties than in an optimally dispersed system.

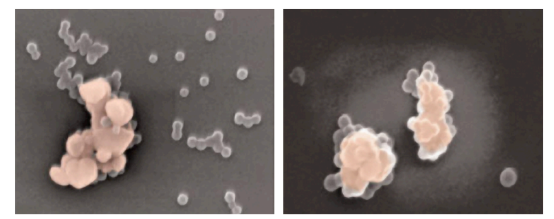

- AVANSE™ MV-100 Resin solves the problem of pigment distribution in the wet and dry states by actually forming latex-pigment composites, where the latex associates with the surface of the pigment particles. This phenomenon is depicted in Figure 1, which shows SEM micrographs of titanium dioxide particles dispersed in a conventional acrylic latex and inAVANSE™ MV-100 Resin.

- There is clearly a greater association of the AVANSE™ MV-100 Resin particles with the TiO₂ particles, such that the TiO₂ surface is partially covered with binder.

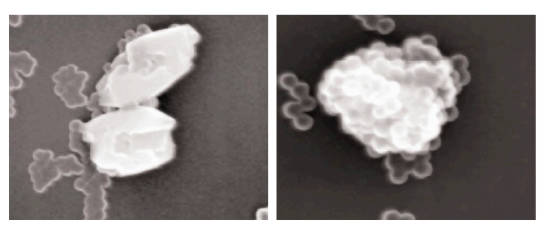

- The latex-pigment composites help to keep the pigment and extender particles separated in the wet paint and provide a more optimal distribution of pigment in the dry film, because the latex particles act as spacers between pigment particles. The result is higher gloss, better hiding, and improved barrier properties (For example, corrosion resistance). The formation of latex-pigment composites is not limited to titanium dioxide, but occurs with other mineral pigments as well. Figure 2 shows a similar situation for calcium carbonate dispersed in a conventional latex versus in AVANSE™ MV-100 Resin.

- The calcium carbonate surface appears to be completely covered by the AVANSE™ MV-100 Resin particles.

- Another key feature of AVANSE™ MV-100 Resin is its ability to self-crosslink at ambient temperatures and still maintain true one-package stability.

- The functional groups present in the resin will crosslink via both oxidative and photolytic curing mechanisms.

- Formulations based on AVANSE™ MV-100 Resin will begin to crosslink as soon as they are applied, and may require about 2 to 4 weeks until some properties have reached their maximum performance level.

- The crosslinked film provides improved dirt pickup resistance, chemical and solvent resistance, and durability.

Figure 1: Left picture shows a SEM micrograph (50K magnification) of TiO₂ dispersed in a conventional acrylic latex polymer. Picture on right shows TiO2 dispersed in AVANSE™MV 100 Resin. The latex particles appear as the smaller, gray spheres, and TiO₂ appears as pink.

Figure 2: Left picture shows a SEM micrograph (50K magnification) of calcium carbonate dispersed in a Conventional acrylic latex polymer. Picture on right shows calcium carbonate dispersed in AVANSE™ MV-100 Resin. The latex particles appear as the smaller, grey spheres, and calcium carbonate appears as white.

- Performance Data

- The typical performance demonstrated by AVANSE™ MV-100 Resin in a gloss white DTM coating formulated at 100 g/L, such as formulations MV-100-1 and MV-100-2, is shown in the Tables and Figures below.

- Although Konig hardness is slightly lower, film hardness as measured by the pencil hardness test is similar to resins with higher Tg and higher VOC requirements such as MAINCOTE™ HG-54D Resin.

- Dirt pickup resistance is also comparable to harder resins after a short air cure, and actually exceeds that of conventional resins after self-crosslinking is allowed to occur, such as after exposure to UV light. Solvent resistance, as measured by MEK double rubs, also improves significantly after a short UV exposure.

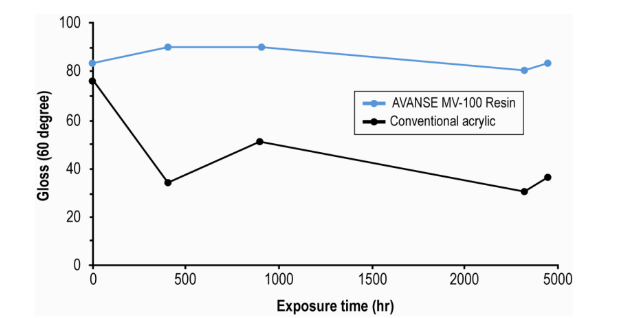

- Gloss potential is high, and durability is also excellent, as demonstrated by the gloss retention after accelerated exposure to UV-A light (Figure 3). Figure 3 compares the gloss retention of AVANSE™ MV-100 Resin with a commercial waterborne acrylic paint based on a conventional resin and formulated at a higher VOC (200 to 250 g/L).

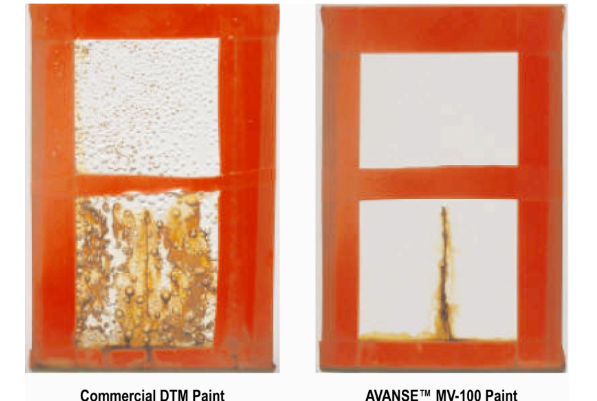

- Corrosion resistance of coatings based on AVANSETM MV-100 Resin is excellent, as demonstrated by Figure 4, which compares it with a commercial waterborne acrylic DTM coating.

Table 1. Typical Performance of AVANSETM MV-100 in an 18 PVC Gloss White DTM Formulation

Gloss (20%/ 60°) 67/84 Heat Age Stability Pass 10 days at 60° C

Freeze-Thaw Stability Pass 3 cycles Roller Stability Pass 10 days Hardness Pencil 2B Konig 13 sec Dirt pickup resistance (initial/final Y-reflectance)¹

1 week air cure 0.89 1 week UV-A exposure 0.99 MEK double rubs (3 mils DFT) 1 week air cure 50 1 week UV-A exposure 300 Humidity resistance (Cleveland condensation cabinet, 2 weeks) No blistering/slight dulling

Gloss Retention

Figure 3: Comparison of gloss retention of UV-A exposure for a gloss white DTM formulation based on AVANSE™ MV-100 Resin and a commercial gloss white DTM based on a conventional VOC resin (200–250 g/L).

Corrosion Performance–Salt Fog Exposure Test

Figure 4: Salt spray resistance at approximately 5 weeks of a gloss white DTM formulation based on AVANSE™ MV-100 Resin and a commercial gloss white DTM based on a conventional VOC resin (200–250 g/L). Paints were applied at 3 mil DFT on hot rolled steel (SSPC SP-5) and dried 1 week prior to exposure according to ASTM B-117.

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000005

- Principal

Storage & Handling

- Handling Information

- Keep combustible and/or flammable products and their vapors away from heat, sparks, flames and other sources of ignition including static discharge.

- Processing or operating at temperatures near or above product flashpoint may pose a fire hazard.

- Use appropriate grounding and bonding techniques to manage static discharge hazards.

- Failure to maintain proper volume level when using immersion heaters can expose tank and solution to excessive heat resulting in a possible combustion hazard, particularly when plastic tanks are used.

- Storage Conditions

Store products in tightly closed original containers at temperatures recommended on the product label.

Other

- Appearance

- Milky-white fluid

- Color (SDS)

- Milky white

- Item Number

- Odor (SDS)

- Ammonia

- Protect from Freezing

- No

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions pH 8.5-9.5 - - Material Composition

Value Units Test Method / Conditions Solid Content 50.0-51.0 % % Volatile Organic Compounds (VOC) max. 100.0 g/L g/L - Mechanical Properties

Value Units Test Method / Conditions Gloss 67.0 - 20° Gloss 67.0 - 60° Hardness 13.0 HV HV - Physical Properties

Value Units Test Method / Conditions Density 8.65 lb/gal lb/gal wet Film Forming Temperature 14.0 °C °C Sieve Fractionation (Retained) 0.0-100.0 ppm ppm 45μm mesh Storage Temperature 1.0-49.0 °F °F Viscosity 0.0-500.0 mPa.s mPa.s Brookfield Viscometer at 25C, Spindle #1, 60 rpm, CPO - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) 100.0 °C °C Water Evaporation Rate (SDS) max. 1.0 % % Butyl acetate = 1, water Melting Point (SDS) 0.0 °C °C Water Relative Density (SDS) 1.06 - Water = 1 Relative Vapor Density (SDS) max. 1.0 - Vapor Pressure (SDS) 17.0 mm Hg mm Hg at 20°C, Water Viscosity (SDS) max. 500.0 mPa.s mPa.s Volatile Content (SDS) 49.0-50.0 % % Water pH (SDS) 8.5-9.5 - - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 540.0 d d