Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Country of Origin

- Function

- Binder

- Product Code

- MITM11280

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

- Product Performance

Application Properties

- AVANSE™ ST-410 Acrylic Emulsion is a 100% acrylic emulsion developed specifically for low VOC exterior semitransparent wood stains.

- The unique polymer stabilization in AVANSE™ ST-410 Acrylic Emulsion helps to extend the workability of this polymer as it dries, giving good flow and lapping on porous surfaces.

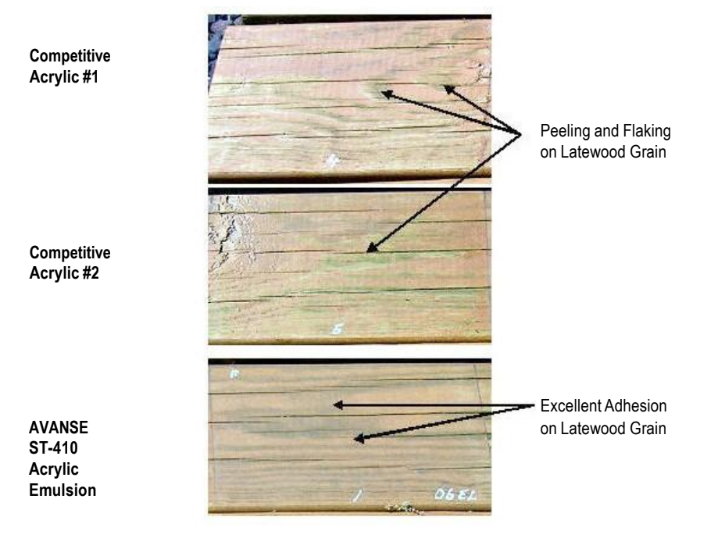

- Adhesion to Metal Based CCA Replacement Wood Preservatives

- The unique interaction of the AVANSE™ ST-410 Acrylic Emulsion with metals also gives excellent adhesion on new wood treated with copper metal based wood preservatives.

Adhesion to Copper Azole Treated Pine

Exposed 6 Months at Horizontal Up

AVANSE™ ST-410 Acrylic Emulsion

AVANSE™ ST-410 Acrylic Emulsion has better adhesion to copper based wood preservatives than competitive acrylic stain binders.

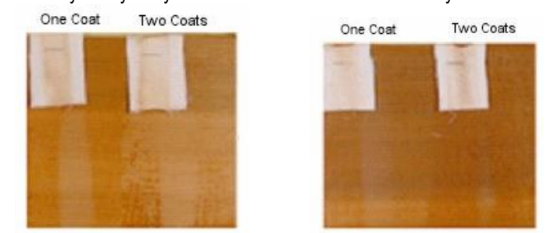

Early Water Resistance and Hardness Development- Stains based on AVANSE™ ST-410 Acrylic Emulsion have very good early water resistance and hardness development on decking substrates.

- Especially on high tannin woods like cedar or redwood, the early water resistance and hardness is much better than water dispersible alkyds or alkyd acrylic hybrids.

- Tannins from these woods can slow the oxidative cure of these systems, giving a tacky, water sensitive film after an overnight dry.

Early Wet Abrasion Resistance on Cedar

16 Hours Dry, 16 Hours Exposure in Fog Box

AVANSE™ ST-410 Acrylic Emulsion Alkyd Acrylic Hybrid Water based Solvent Alkyd

AVANSE™ ST-410 Acrylic Emulsion has excellent wet abrasion resistance in one or two coats after an overnight dry. It is better than an alkyd/acrylic semitransparent stain and a solvent based semitransparent stain on cedar.

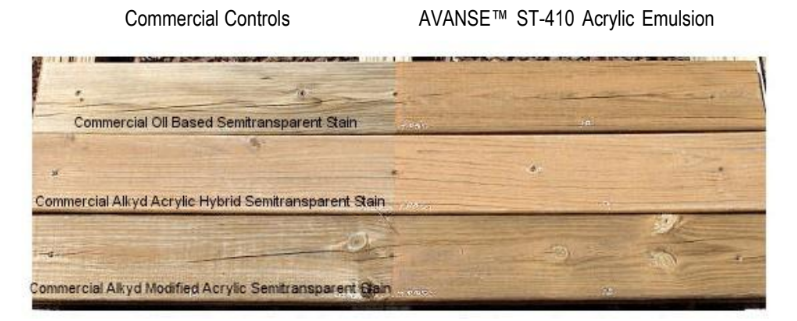

Exterior Durability

- The 100% acrylic backbone in AVANSE™ ST-410 Acrylic Emulsion gives excellent exterior durability.

- Properly formulated AVANSE™ ST-410 Acrylic Emulsion stains protect the wood and provide a long service life.

- Exposure studies have shown that stains based on AVANSE™ ST-410 Acrylic Emulsion have exterior durability equal to or better than commercial solvent or water based semitransparent stains.

- The picture below shows the excellent fade resistance and adhesion of the AVANSE™ ST-410 Acrylic Emulsion compared to commercial semitransparent stains.

30 Month Exterior Durability

Exposed Horizontal Up on ACQ Treated Pine

AVANSE™ ST-410 Acrylic Emulsion has better fade resistance, adhesion and erosion resistance than the commercial semitransparent stains.

- Key Features

- Excellent initial appearance–crisp colors that bring out the natural warmth of the wood

- Outstanding adhesion

- Superior color retention

- Durable longer lasting coating

Environmentally Advanced

- Replaces traditional solvent based technologies

- Does not require coalescent

- No heavy metal driers

- APEO free

Unique particle stabilization

- Excellent flow and wetting

- Very good lapping

- Rapid hardness development – even over high tannin woods

- Excellent early water resistance

Applications & Uses

- Coating End Applications

- Compatible Substrates & Surfaces

- Markets

- Applications

Properties

- Physical Form

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000005

- Principal

Storage & Handling

- Storage Conditions

Store products in tightly closed original containers at temperatures recommended on the product label.

- Handling Information

- Keep combustible and/or flammable products and their vapors away from heat,sparks, flames and other sources of ignition including static discharge.

- Processing or operating at temperatures near or above product flashpoint may pose a fire hazard.

- Use appropriate grounding and bonding techniques to manage static discharge hazards.

- Failure to maintain proper volume level when using immersion heaters can expose tank and solution to excessive heat resulting in a possible combustion hazard, particularly when plastic tanks are used.

Other

- Appearance

- Milky white liquid

- Color (SDS)

- White

- Item Number

- Odor (SDS)

- Ammonia

- Other Hazards

- No data available

- Protect from Freezing

- Yes

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions pH 8.5-9.5 - - Material Composition

Value Units Test Method / Conditions Solid Content 37.0 % % - Physical Properties

Value Units Test Method / Conditions Density 8.69 lb/gal lb/gal Density 9.34 lb/gal lb/gal Dry Solids Basis Film Forming Temperature max. 3.0 °C °C Storage Temperature 34.0-120.0 °F °F Viscosity max. 1000.0 cPs cPs Brookfield Viscometer 60 rpm, #2 spindle - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) 100.0 °C °C Water Evaporation Rate (SDS) max. 1.0 % % Butyl acetate = 1, water Melting Point (SDS) 0.0 °C °C Water Relative Density (SDS) 1.0-1.2 - Water = 1 Relative Vapor Density (SDS) max. 1.0 - Vapor Pressure (SDS) 17.0 mm Hg mm Hg at 20°C, Water Viscosity (SDS) 100.0-1000.0 mPa.s mPa.s Volatile Content (SDS) 62.0-65.0 % % pH (SDS) 8.5-9.5 - - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 540.0 d d