Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Carrier

- Chemical Family

- Function

- Crosslinking Agent

- Product Code

- MITM10051

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

- Product Features

Pot Life

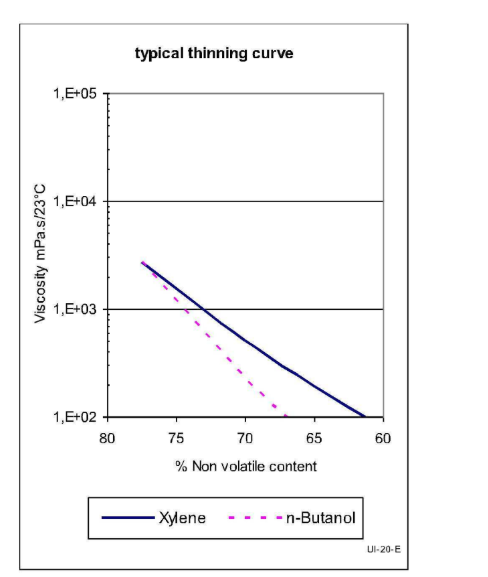

- To extend catalyzed pot life of the formulation, addition of primary alcohols, such as n-butanol, ethanol, and methanol, is required at concentrations of 10-5% on total resin solids.

- Faster evaporating alcohols will improve speed of dry.

- Product Benefits

- High film build

- Low odor

- Fast drying

- Excellent block resistance

- Low formaldehyde release

Applications & Uses

- Coating End Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Cure Method

- Markets

- Applications

- Product Applications

- Acid curing wood coating applications

Properties

- Physical Form

- Soluble In

Technical Details & Test Data

- Catalysis Information

- CYMEL® UI-20-E Resin responds best to sulfonic acid catalysts, like CYCAT' 4040.

- Generally, 6-10% CYCAT 4040 catalyst on total binder solids of the formulation is sufficient to obtain fast drying behavior at room temperature.

- Technical Data

- Backbone Polymer Selection

- CYMEL® UI-20-E Resin is a very effective crosslinking agent for backbone polymer resins containing hydroxyl functional groups, such as alkyd, polyester or acrylic resins.

- CYMEL® UI-20-E Resin has high reactivity and a high tendency for self- condensation providing fast drying films with good gloss, hardness and block resistance.

- The optimum level of CYMEL® UI-20-E Resin in an acid curing wood coating formulation should be in the range of 25-35% on total resin solids.

- To obtain formulations with optimum resistance properties, addition of a melamine resin, such as CYMEL MB 98 resin, at levels of 5-10% on total resin solids is recommended.

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000001

- Principal

Storage & Handling

- Storage Conditions

- CYMEL® UI-20-E Resin has a shelf life of 24 months from date of manufacture when stored at temperatures between 5℃ and 30C.

- Although low temperatures are not detrimental to stability, the viscosity of the product will increase making the resin more difficult to pump or pour.

- Product viscosity can be returned to normal by gentle re-warming, however, care should be taken to avoid excessive localized heating as this can cause an irreversible increase in viscosity.

Other

- Appearance

- Clear liquid

- Appearance (SDS)

- Viscous liquid

- Color (SDS)

- Colorless

- IATA/ICAO Proper Shipping Name

- Resin solution

- IATA/ICAO UN Number

- UN1866

- IMO/IMDG Proper Shipping Name

- Resin solution

- IMO/IMDG UN Number

- UN1866

- Insoluble in (SDS)

- Water

- Item Number

- Odor (SDS)

- Formaldehyde and ethanol

- Other Hazards

- Polymerization may occur from excessive heat, contamination or exposure to direct sunlight .

- Protect from Freezing

- No

- TDG Canada Proper Shipping Name

- Resin solution

- TDG Canada UN Number

- UN1866

- Temperature Control

- Yes

- USA/DOT Proper Shipping Name

- Resin solution

- USA/DOT UN Number

- UN1866

- Chemical Properties

Value Units Test Method / Conditions Free Formaldehyde Content 0.5 % Sulfite Method - Material Composition

Value Units Test Method / Conditions Non-Volatile Content 76.0-80.0 % at 105°C, 1 h, Pan - Optical Properties

Value Units Test Method / Conditions Color Scale max. 50.0 APHA Color Scale max. 50.0 Gardner ISO 6271 - Physical Properties

Value Units Test Method / Conditions Storage Temperature -4.0-86.0 °F Viscosity 1700.0-3500.0 mPa.s at 23°C - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Density (SDS) 1.01 g/cm³ at 25°C Evaporation Rate (SDS) max. 1.0 % Flash Point (SDS) 25.0 °C SetaFlash Closed Cup Volatile Content (SDS) 22.0 %(W/W) - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 24.0 mo