Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Country of Origin

- Function

- Monomer

- Product Code

- MITM00382

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Performance Highlights

EBECRYL® 350 is characterized by:

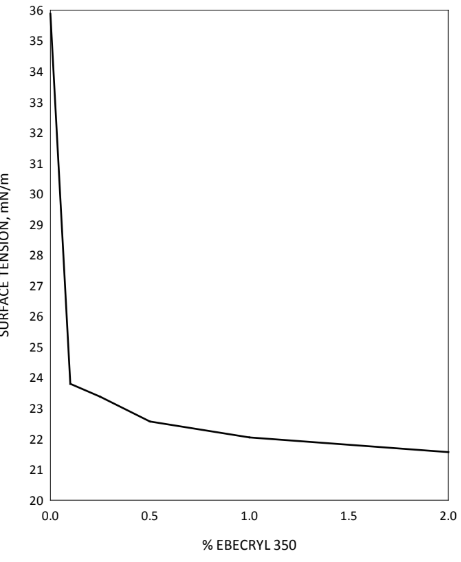

- Low surface tension

- Low viscosity

- Good compatibility with other acrylates

- Non-migratory

UV/EB cured products based on EBECRYL® 350 are characterized by the following performance properties:

- Low COF, increased slip

- Resistance to blocking

- High gloss

- Good mar resistance

The actual properties of UV/EB cured products also depend on the selection of other formulation components such as reactive diluents, additives and photoinitiators.

Applications & Uses

- Application Method

- Coating End Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Cure Method

- Markets

- Applications

- Product Applications

Formulated UV/EB curable products containing EBECRYL® 350 may be applied via direct or reverse roll, offset gravure, metering rod, slot die, knife over roll, air knife, immersion and spin coating methods as well as screen printing. EBECRYL® 350 is recommended for use in:

- Overprint varnishes

- Clear coatings on paper, plastics and metal

- Release coatings

Usage levels between 0.5% and 2.0% by weight of the total formulation are generally sufficient to provide satisfactory slip.

Properties

- Physical Form

Technical Details & Test Data

- Surface Tension Graph

Effect on the surface tension of TMPTA

Packaging & Availability

Principal Information

- Group Principal Number

- S000001

- Principal

Storage & Handling

- Storage Conditions

- Care should be taken not to expose the product to high temperature conditions, direct sunlight, ignition sources, oxidizing agents, alkalis or acids. This might cause uncontrollable polymerization of the product with the generation of heat.

- Storage and handling should be in stainless steel, amber glass, amber polyethylene or baked phenolic lined containers. Procedures that remove or displace oxygen from the material should be avoided. Do not store this material under an oxygen free atmosphere.

- Dry air is recommended to displace material removed from the container. Wash thoroughly after handling. Keep container tightly closed. Use with adequate ventilation.

Other

- Appearance

- Cloudy liquid

- Appearance (SDS)

- Clear liquid

- Color (SDS)

- Clear pale yellow

- Insoluble in (SDS)

- Water

- Item Number

- Odor (SDS)

- Ester like

- Other Hazards

- Polymerization may occur from excessive heat ,contamination or exposure to direct sunlight , Contact with skin may cause a cross-allergic reaction in persons already sensitized to acrylates.

- Protect from Freezing

- Yes

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Application Information

Value Units Test Method / Conditions Dosage (Use Level) 0.5-2.0 %(W/W) %(W/W) - Chemical Properties

Value Units Test Method / Conditions Acid Value max. 7.0 mg KOH/g mg KOH/g - Material Composition

Value Units Test Method / Conditions Oligomer Content 100.0 %(W/W) %(W/W) - Optical Properties

Value Units Test Method / Conditions Color Scale max. 10.0 Gardner Gardner Gardner Color Scale - Physical Properties

Value Units Test Method / Conditions Density 1.05 g/mL g/mL at 25°C Storage Temperature 59.0-104.0 °F °F Surface Tension 21.6 mN/m mN/m mN/m = dynes/cm Viscosity 200.0-500.0 cPs cPs at 25°C - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) min. 100.0 °C °C Density (SDS) 1.05 g/cm³ g/cm³ Flash Point (SDS) 265.0 °C °C Cleveland Open Cup Vapor Pressure (SDS) max. 1.33 hPa hPa at 20°C Viscosity (SDS) 200.0-500.0 mPa.s mPa.s at 25°C Volatile Content (SDS) max. 0.3 %(W/W) %(W/W) - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 730.0 d d