Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Function

- Binder

- Product Code

- MITM11384

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

- Performance Advantages

Improved Toughness and Hardness

- RHOPLEX® HG-95P Emulsion Polymer was developed for use in low VOC aqueous gloss enamels that offer improved hardness, toughness, and resistance properties and represents a viable alternative to solvent-based gloss paints.

- RHOPLEX® HG-95P Emulsion Polymer has a lower coalescent demand than most other gloss copolymers in a similar hardness range.

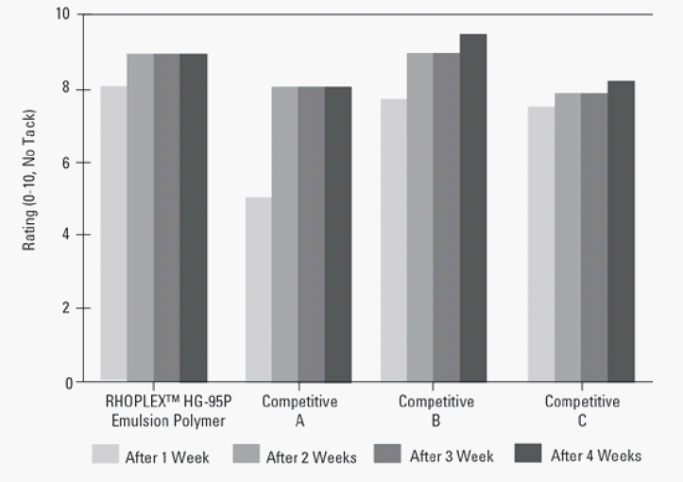

- This reduced coalescent demand improves early block resistance, and some formulations develop room temperature block resistance after as little as six hours drying time. RHOPLEX® HG-95P Emulsion Polymer has very good block and print resistance under practical "summer day" conditions as shown in Figure 2

- The thermoplastic behavior of conventional acrylic emulsion binders can cause paint films to soften at high temperatures and high humidity. RHOPLEX® HG-95P Emulsion Polymer develops sufficient thermoset characteristics to improve performance under these conditions making it ideal for applications such as doors, window frames, and bookcases.

Improved Resistance to Household Chemicals

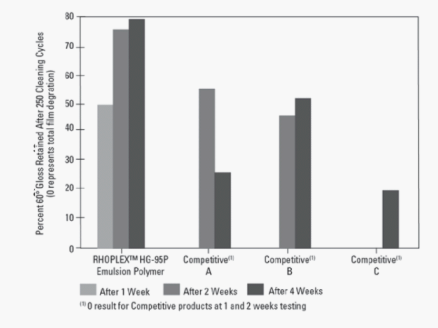

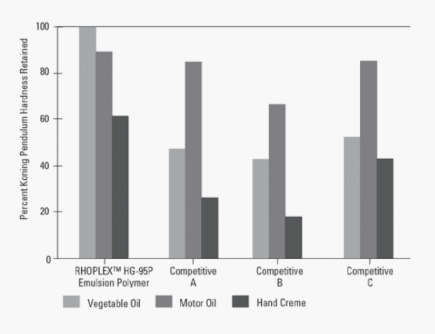

- RHOPLEX® HG-95P Emulsion Polymer offers improved resistance to household chemicals to existing latex technology. Figures 3 and 4 describe the significant resistance improvement over conventional gloss copolymer technology.

- The excellent chemical resistance and film properties make RHOPLEX® HG-95P HG-95P Emulsion Polymer ideal for demanding applications.

- Excellent Adhesion Gloss enamels based on RHOPLEX® HG-95P Emulsion Polymer demonstrate excellent adhesion qualities over a variety of substrates.

- Over five years of exterior exposure data has been collected on this polymer.

- Very good exterior performance has been found in gloss enamels based on RHOPLEX® HG-95P Emulsion Polymer.

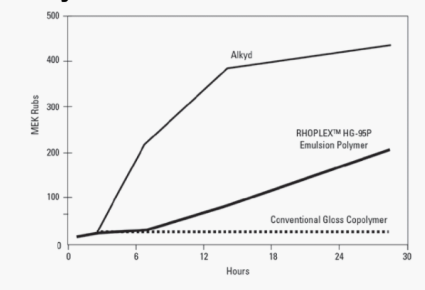

Figure 1: Solvent Resistance of RHOPLEX® HG-95P Emulsion Polymer

Figure 2: Effect Dry Time on High Temperature Block Resistance (120°F/30 min/2 psi)

Figure 3: Effect of Dry Time on Household Chemical Resistance Test

Figure 4: Effect of Household Oils on Film Integrity After 16-Hour Spot

- Product Benefits

- Early and ultimate block and print resistance

- Excellent alkyd adhesion

- Excellent resistance to household chemicals, grease, and hand creams

- Combines low coalescent demand with low VOC (below 200 g/l) capabilities 100% acrylic composition

Applications & Uses

- Applicable Processes

- Application Area

- Coating End Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Markets

- Applications

Properties

- Physical Form

Technical Details & Test Data

- Technical Data

New Ambient Temperature Crosslinking Technology

- RHOPLEX®; HG-95P Emulsion Polymer offers the benefits of ambient temperature crosslinking chemistry in a true one-pack system.

- Paints formulated with RHOPLEX®; HG-95P Emulsion Polymer will form a covalently crosslinked network.

- RHOPLEX™ HG-95P Emulsion Polymer will oxidatively cure after the coalescing of latex particles to form a crosslinked film with improved hardness, toughness, and resistance properties.

- Aqueous gloss enamels based on RHOPLEX®; HG-95P Emulsion Polymer will have very similar drying characteristics to conventional latex paints.

- Enamels exhibit very good early properties and will continue to improve during the curing process which may require 2-4 weeks for some properties to fully develop.

Packaging & Availability

Principal Information

- Group Principal Number

- S000005

- Principal

Storage & Handling

- Storage Conditions

Store products in tightly closed original containers at temperatures recommended on the product label.

- Handling Information

- Keep combustible and/or flammable products and their vapors away from heat, sparks, flames and other sources of ignition including static discharge.

- Processing or operating at temperatures near or above product flashpoint may pose a fire hazard.

- Use appropriate grounding and bonding techniques to manage static discharge hazards.

- Failure to maintain proper volume level when using immersion heaters can expose tank and solution to excessive heat resulting in a possible combustion hazard, particularly when plastic tanks are used.

Other

- Appearance

- Milky white liquid

- Color (SDS)

- White milky

- Item Number

- Odor (SDS)

- Ammonia

- Protect from Freezing

- Yes

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Chemical Properties

Value Units Test Method / Conditions pH 8.5-9.5 - - Material Composition

Value Units Test Method / Conditions Solid Content 46.5 % % - Physical Properties

Value Units Test Method / Conditions Bulking Value 0.1053 gal/lb gal/lb dry solids Bulking Value 0.114 gal/lb gal/lb wet Density 8.84 g/cm³ g/cm³ Film Forming Temperature 26.0 °C °C Storage Temperature 34.0-120.0 °F °F Viscosity max. 500.0 cPs cPs Brookfield Viscometer at 60 rpm, spindle 2 - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) 100.0 °C °C Evaporation Rate (SDS) max. 1.0 % % Butyl acetate = 1 Melting Point (SDS) 0.0 °C °C Relative Vapor Density (SDS) max. 1.0 - Air = 1 Specific Gravity (SDS) 1.0-1.2 - Water = 1 Vapor Pressure (SDS) 17.0 mm Hg mm Hg at 20°C Viscosity (SDS) 10.0-120.0 mPa.s mPa.s Volatile Content (SDS) 53.0-54.0 % % Water pH (SDS) 8.5-9.5 - - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 0.0 d d