Enhanced TDS

Identification & Functionality

- Blend

- No

- CASE Ingredients Functions

- Chemical Family

- Country of Origin

- Function

- Binder

- Product Code

- MITM11404

- Single Ingredient

- Yes

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Labeling Claims

Applications & Uses

- Application Method

- Coating End Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Markets

- Applications

Properties

- Physical Form

- Key Properties

Viscosity Control

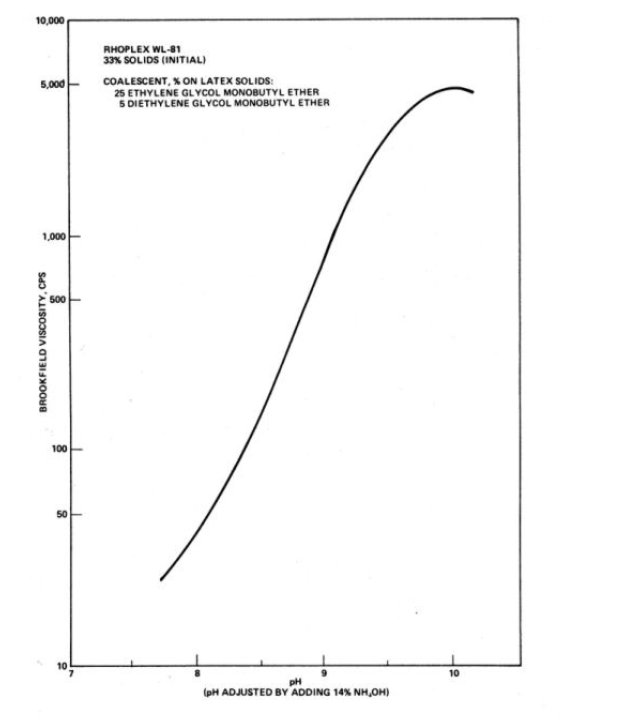

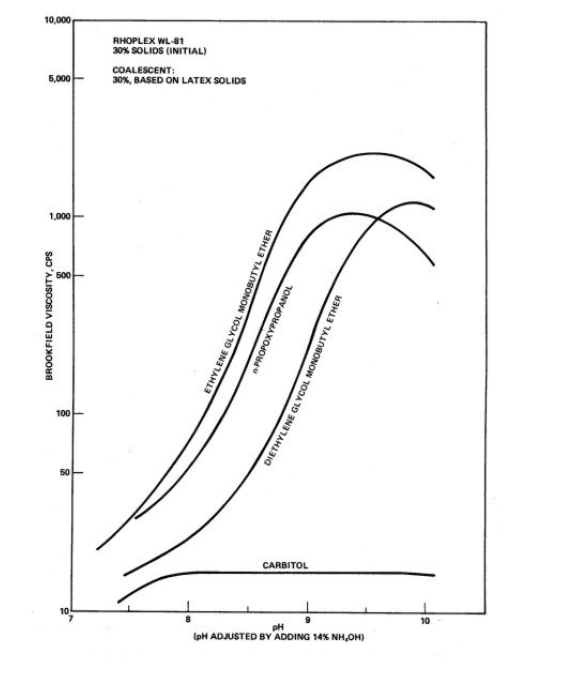

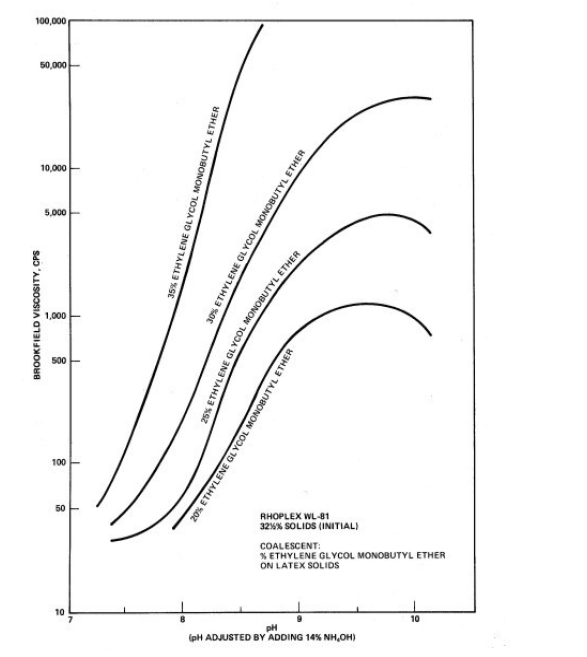

RHOPLEX® WL-81 polymer is designed so that external thickeners are not required. Many of the glycol ethers on the market today will swell the latex particles, thereby increasing their effective volume and increasing the viscosity. The addition of ammonia or other amines (e.g., dimethylethanolamine) to the swollen particles will further increase viscosity.

Technical Details & Test Data

- Technical Data

Figure 1: Typical pH vs Viscosity Profile

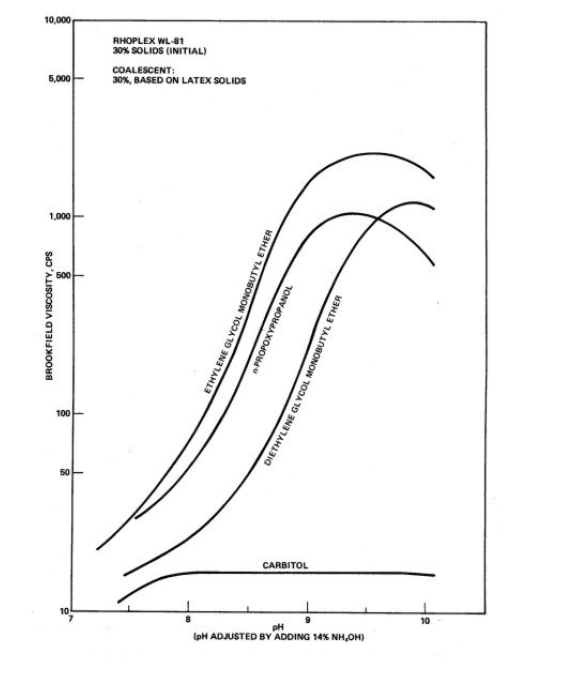

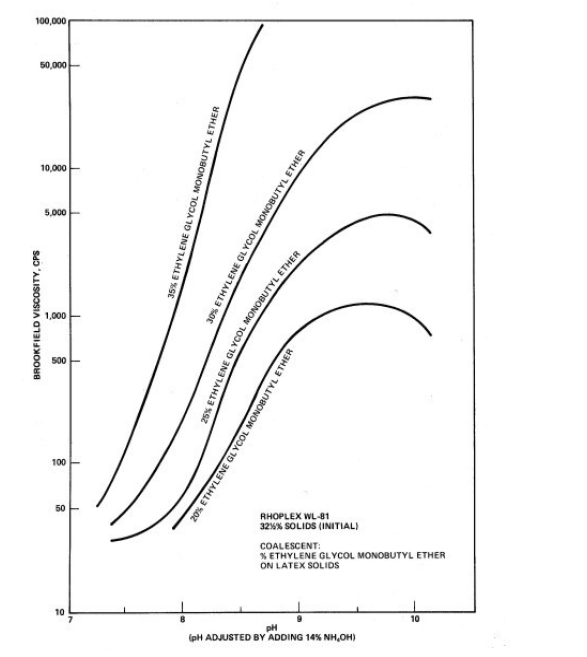

- The degree of swelling by various coalescents is illustrated in Figure II. The effect of the level of coalescent on viscosity response is shown in Figure III. The proper choice and level of coalescents combined with the use of ammonia or organic amine enable the formulator to control the viscosity response.

- Pigmentation will also affect viscosity. Pigments with low-soluble ion concentration (e.g., Snowflake™ calcium carbonate extender) will reduce slightly the viscosity response to ammonia or other amines. Pigments with a higher soluble ion content (e.g., medium chrome and zinc yellow) will have larger effects. In formulating with these pigment types, the viscosity is more readily controlled by using a coalescent concentration/solids approach and depending less on pH response.

Figure 2: Effect of Coalescent Type on Viscosity

Figure 3: Effect of Coalescent Concentration on Viscosity

- Technical Data

- Technical Data

- Technical Data

Safety & Health

- Safety Precautions

Based on its composition, RHOPLEX® WL-81 polymer is not expected to be acutely toxic via single oral or dermal exposure. It may be a mild to moderate skin, eye, or respiratory irritant.

Packaging & Availability

- Packaging Type

Principal Information

- Group Principal Number

- S000005

- Principal

Other

- Appearance

- Milky white liquid

- Color (SDS)

- White

- Item Number

- Odor (SDS)

- Ammoniacal

- Other Hazards

- Data not available

- Protect from Freezing

- Yes

- Temperature Control

- Yes

- USA/DOT UN Number

- Not Applicable

- Application Information

Value Units Test Method / Conditions Application Temperature 60.0 °C °C - Chemical Properties

Value Units Test Method / Conditions pH 7.5 - - Material Composition

Value Units Test Method / Conditions Solid Content 41.5 %(V/V) %(V/V) - Mechanical Properties

Value Units Test Method / Conditions Gloss 50.0 - 20° Gloss 80.0 - 60° Hardness 8.0 HV HV 1 week - Physical Properties

Value Units Test Method / Conditions Density 8.6 lb/gal lb/gal at 25°C Film Forming Temperature 57.0 °C °C Specific Gravity 1.036 - Storage Temperature 34.0-120.0 °F °F Viscosity 40.0-500.0 cPs cPs Brookfield Viscometer At 25°C, #2, 30 Rpm - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point (SDS) 100.0 °C °C Evaporation Rate (SDS) max. 1.0 % % Butyl Acetate=1 Melting Point (SDS) 0.0 °C °C Relative Vapor Density (SDS) max. 1.0 - Air=1 Specific Gravity (SDS) 1.0-1.2 - Water = 1 Vapor Pressure (SDS) 17.0 mm Hg mm Hg at 20°C Viscosity (SDS) 40.0-290.0 mPa.s mPa.s Volatile Content (SDS) 58.0-59.0 % % pH (SDS) 7.4-8.0 - - Shelf Life & Stability

Value Units Test Method / Conditions Shelf Life 540.0 d d